Tired of high heating bills and uneven temperatures throughout your home? Graphene heating film represents the next generation of home heating technology, offering homeowners, builders, and energy-conscious consumers a smarter way to stay warm while cutting costs.

This innovative radiant heating technology uses ultra-thin graphene layers to generate consistent, efficient heat that transforms how we think about modern home heating. Unlike traditional systems that heat air and create temperature imbalances, graphene heating panels deliver direct infrared warmth that feels natural and comfortable.

We’ll explore how graphene heating film achieves up to 40% energy savings compared to conventional electric heating, why its easy installation makes it perfect for both new construction and renovations, and how this smart heating technology provides superior comfort through advanced heating science that eliminates cold spots and reduces maintenance headaches.

Revolutionary Graphene Technology Transforms Home Heating

Ultra-thin graphene film generates heat through electrical power

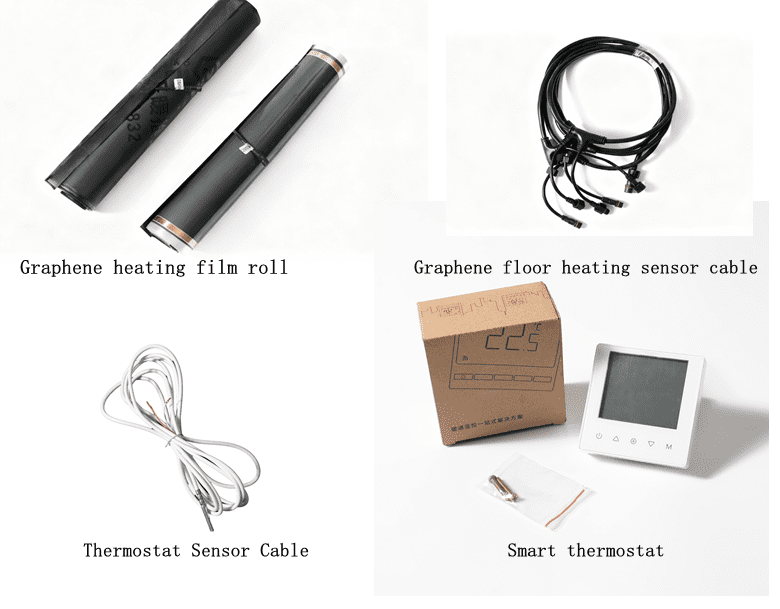

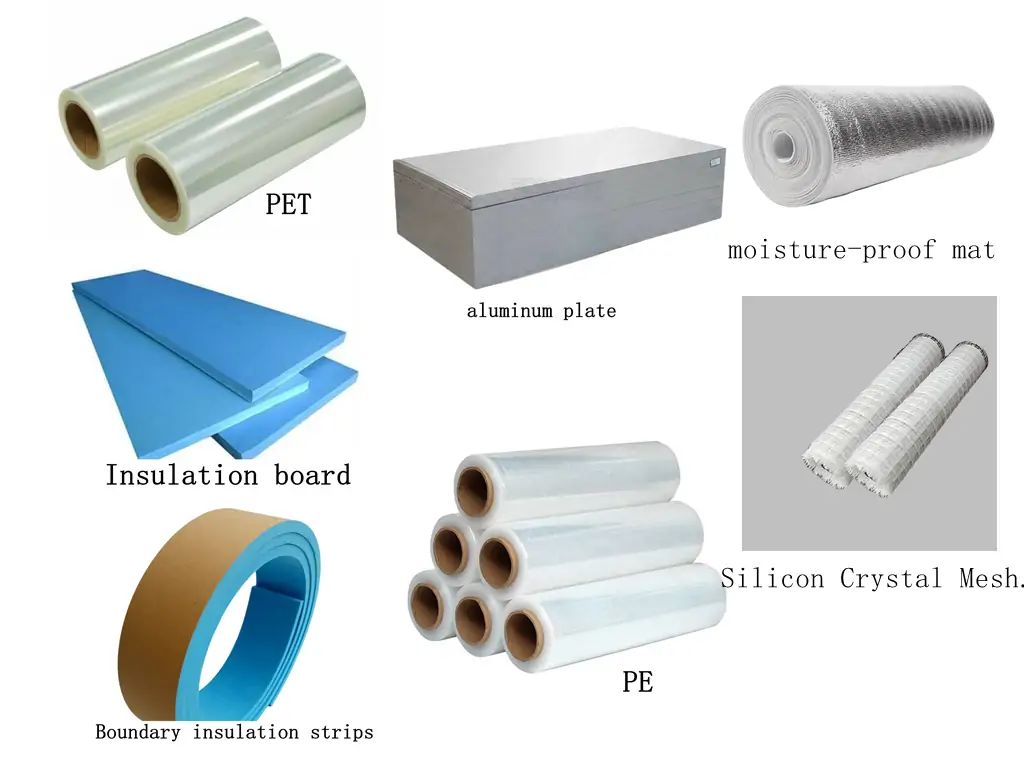

Graphene heating film represents a breakthrough in modern home heating technology, utilizing the exceptional properties of graphene – a single-layer carbon atom material with a thickness of only 0.335 nm. This revolutionary heating solution consists of a composite film made from highly conductive graphene and polyester, equipped with current-carrying strips and protected by an insulation layer.

The heating mechanism operates through a sophisticated process where electrons flow through the graphene heating film upon electrical activation. These electrons collide and create friction with the carbon atoms within the graphene structure, generating heat through far-infrared radiation. The electrothermal conversion efficiency reaches an impressive 99%, significantly outperforming traditional heating systems that typically achieve only 70% conversion rates.

Unlike conventional heating methods that rely on resistors or heat transfer fluids, graphene heating panels emit far-infrared radiation with wavelengths between 5-12 micrometers. This specific range is perfectly absorbed by the human body, providing direct heat transfer to people and objects rather than merely warming ambient air. The hexagonal honeycomb structure of graphene’s single-layer carbon atoms creates a stable molecular framework with exceptional thermal conductivity reaching up to 5,300W/mK.

Silent operation with uniform heat distribution

Graphene home heating systems operate in complete silence, eliminating the noise commonly associated with traditional heating methods. The infrared heating technology differs fundamentally from conventional convection systems by heating people and objects directly without passing through ambient air, ensuring rapid temperature rise and gentle, even heat distribution throughout the space.

The uniform heat distribution characteristic stems from graphene’s exceptional thermal conductivity and stable lattice structure. When external force is applied, the carbon atoms’ surface bends and deforms while maintaining structural integrity, preventing the need for atomic rearrangement. This flexibility ensures consistent heat output across the entire heating surface.

The temperature gradient created by graphene heating film follows a natural bottom-to-top pattern, maintaining optimal thermal comfort with warm floors and cooler ceiling areas. This distribution method reduces temperature imbalances between different room areas, creating an ideal environment where temperatures remain stable throughout the heated space. The system maintains temperature and humidity within the most suitable ranges for human comfort while providing far-infrared therapeutic effects that can improve blood circulation and promote metabolism.

No mechanical components required for maintenance-free heating

Graphene heating systems eliminate the need for mechanical components entirely, offering a maintenance-free heating solution that stands in stark contrast to traditional water-based systems or conventional electric heaters. The absence of moving parts, pumps, fans, or complex mechanical assemblies means there are no components subject to wear, breakdown, or regular servicing requirements.

The stability of graphene’s molecular structure ensures long-term performance without degradation. Unlike ordinary electric heating systems that experience significant heat attenuation after one to two years of use, resulting in power consumption several times higher than initial operation, graphene heating film maintains consistent performance throughout its lifespan. The carbon-carbon bonds within graphene measure only 1.42 angstroms, creating incredibly strong interatomic forces that resist lattice defects and foreign atom interference.

This maintenance-free operation extends the system’s lifespan to 50-70 years, essentially matching the building’s structural lifetime. The durable construction withstands environmental pressures, maintains waterproof and corrosion-resistant properties, and demonstrates excellent weather resistance. The stable performance eliminates the need for annual pipe cleaning required by traditional water heating systems or the frequent repairs associated with mechanical heating components, making graphene heating installation a truly set-and-forget solution for modern homes.

Exceptional Energy Efficiency Delivers Significant Cost Savings

40% Energy Savings Compared to Traditional Electric Radiators

Now that we have covered the revolutionary technology behind graphene heating systems, let’s examine the remarkable energy efficiency that makes this innovation truly transformative. Laboratory-tested performance data reveals that graphene heating film delivers an impressive 40% energy savings on average when compared to traditional electric radiators. This significant reduction in energy consumption stems from the unique properties of graphene’s molecular structure and its superior heat generation capabilities.

The energy savings were validated through comprehensive testing conducted by professors from the University of Genoa, working through their spin-off BuildTech srl. These rigorous technical tests and simulations demonstrated not only the high thermal conductivity of graphene heating systems but also their ability to maintain consistent performance while consuming substantially less power than conventional heating methods. The technology proves competitive even with heat pumps, while offering improved installation and maintenance cost advantages.

Building-scale simulations directly compared graphene paint heating systems with floor radiant systems powered by heat pumps. The results consistently demonstrated greater energy efficiency of the graphene system, with lower annual energy consumption and reduced operating costs. This performance advantage translates into tangible cost savings for homeowners while supporting broader energy transition and emission reduction goals.

99% Electric-to-Heat Conversion Rate Maximizes Efficiency

The exceptional efficiency of graphene heating film is fundamentally rooted in its near-perfect electric-to-heat conversion rate. Through the Joule effect, graphene paint generates heat with remarkable efficiency, converting virtually all electrical input into usable thermal energy. This process occurs through long-wave infrared radiation, a low-energy, non-harmful form of heat that doesn’t warm the air but instead acts directly on objects and surfaces.

This direct heating approach eliminates the energy losses typically associated with conventional heating systems that must first heat air before transferring warmth to occupants. The coherence between absorbed power and obtained temperature has been confirmed through extensive testing on various substrates, including drywall, PVC, and polyurethane sandwich panels. These tests verified the system’s electrical stability and quick response to current variations, ensuring consistent performance across different applications.

The radiant heating technology ensures stable thermal distribution without stratification, meaning heat is distributed uniformly throughout the space rather than creating hot and cold zones. This uniform distribution maximizes comfort while minimizing energy waste, as there’s no need to overheat certain areas to compensate for inadequate coverage elsewhere.

Low Power Consumption at Only 35W Per Square Meter

With this in mind, the power efficiency of graphene heating film becomes even more impressive when examining its actual consumption rates. At full capacity, graphene heating surfaces can exceed 110°C while maintaining an average consumption of only 35 watts per square meter. This remarkably low power consumption makes the technology ideal for heating buildings without placing excessive demands on electrical systems.

The low power requirements open new possibilities for integration with renewable energy sources and smart home systems. Unlike traditional heating systems that require significant electrical loads, graphene heating film can operate efficiently even in buildings with limited electrical capacity. This characteristic makes it particularly suitable for retrofit applications where existing electrical infrastructure might not support high-consumption heating systems.

The absence of mechanical components further contributes to the system’s efficiency profile. Without pumps, fans, or other moving parts that consume additional energy, graphene heating film maintains its low power consumption throughout its operational life. This design simplicity not only reduces energy costs but also eliminates maintenance requirements associated with mechanical heating systems, providing long-term operational savings alongside the immediate energy efficiency benefits.

Advanced Heating Science Provides Superior Comfort

Far-infrared radiation heats bodies directly instead of warming air

Graphene heating film utilizes far-infrared radiation technology that fundamentally changes how homes are heated. Unlike traditional heating systems that waste energy heating the air first, this infrared heating systems technology works just like the sun by directly heating people, furniture, walls, floors, and surfaces throughout the room. This direct heating method creates a more comfortable environment while using significantly less energy than conventional baseboard heaters, wall heaters, and forced-air systems.

The radiant heating technology eliminates the common problems associated with traditional heating methods. While conventional systems create drafts and cold spots with temperature differences as much as 10 degrees from floor to ceiling, graphene heating panels provide uniform temperature distribution with only minor 2-4 degree variations throughout the room. This consistent heating eliminates the hot ceiling and cold floor effect typical of convection-type heating systems.

Joule effect creates instant 10-second rapid heating response

The graphene heating film leverages the Joule effect to deliver exceptional heating performance that brings cold rooms to comfortable levels within minutes of activation. This rapid response capability allows for zone-controllable heating, enabling homeowners to turn panels on and off as needed, similar to controlling lights when entering or leaving a room.

This instant heating capability makes smart heating technology particularly effective for energy management. Users can adopt a “vacancy setback” habit, heating only occupied spaces, which results in significant energy savings and lower utility bills. The quick response time means there’s no need to maintain constant heating in unused areas, maximizing the efficiency of the energy efficient heating systems.

Brownian motion of carbon atoms generates therapeutic heat waves

The advanced science behind graphene heating panels involves the Brownian motion of carbon atoms, which generates therapeutic far-infrared heat waves. These heat waves specifically target water molecules in the human body, which comprises approximately 84% water, allowing the heat to penetrate and warm people faster, healthier, and safer than conventional heating sources.

This therapeutic heating provides multiple health benefits including reduced muscle and joint pain, decreased joint stiffness, increased flexibility, and improved cardiovascular circulation. The far-infrared wavelengths produced by the carbon atoms create a penetrating heat that promotes better health outcomes while maintaining optimal comfort levels.

The graphene home heating system also produces beneficial negative ions, creating that wonderful, exhilarating feeling similar to standing by a waterfall or experiencing the fresh air after rain. Unlike conventional electrical heaters that generate positive ions with deleterious health effects, this technology enhances indoor air quality while providing clean, comfortable therapeutic heat without odors, flames, or forced air circulation.

Easy Installation and Versatile Application Options

Applies like regular paint on any common building material

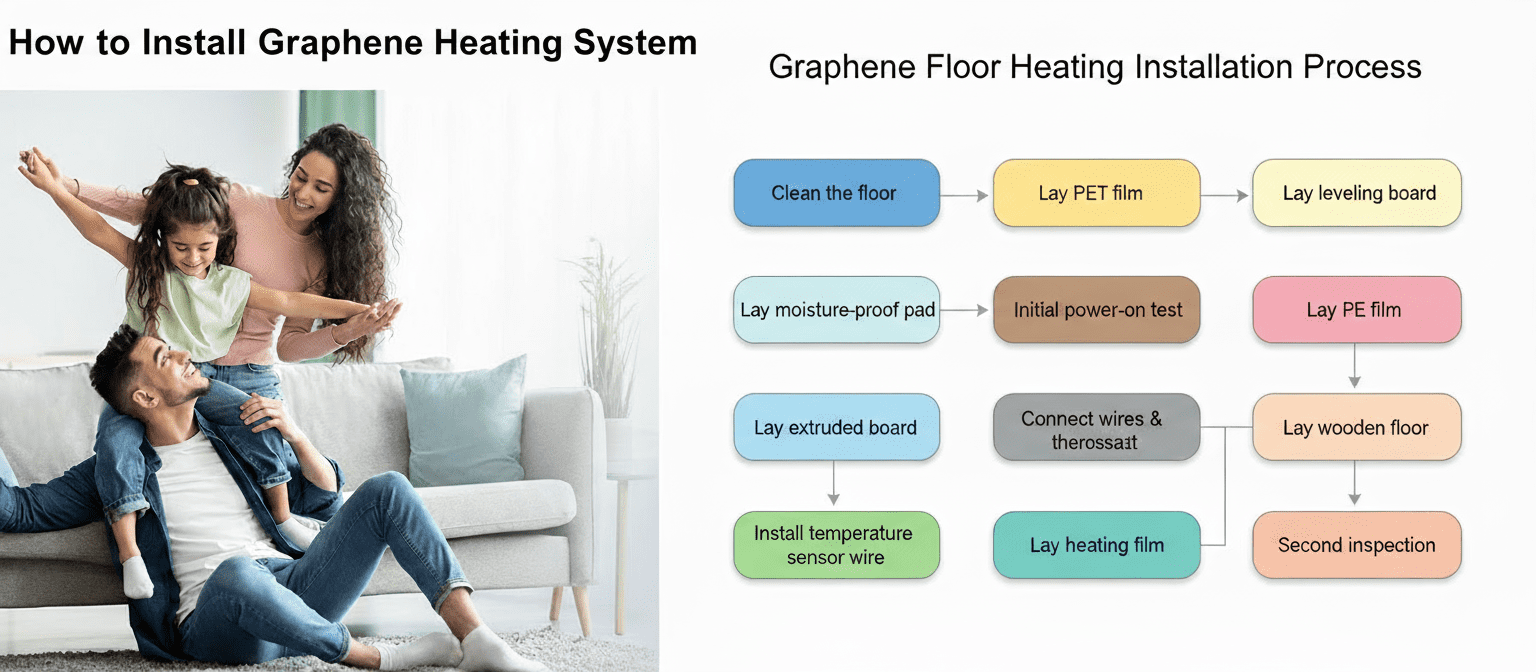

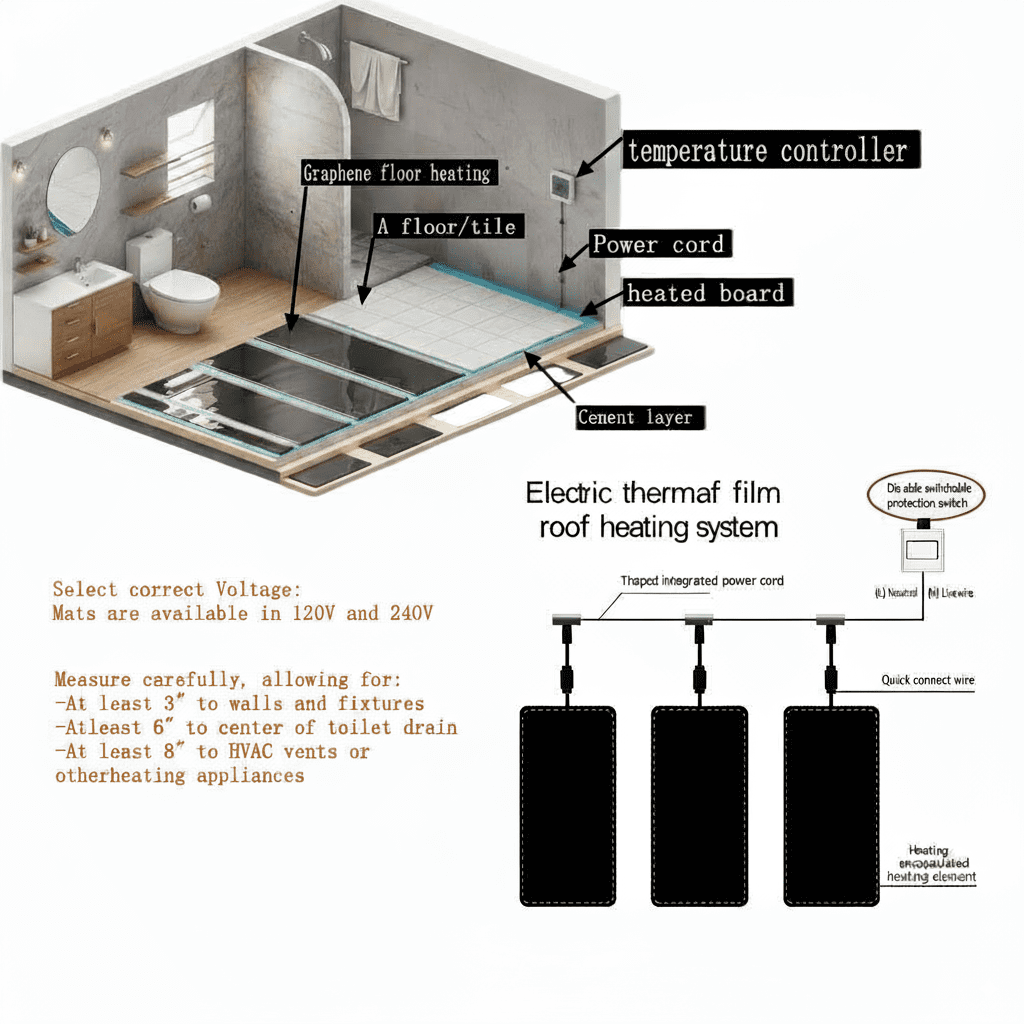

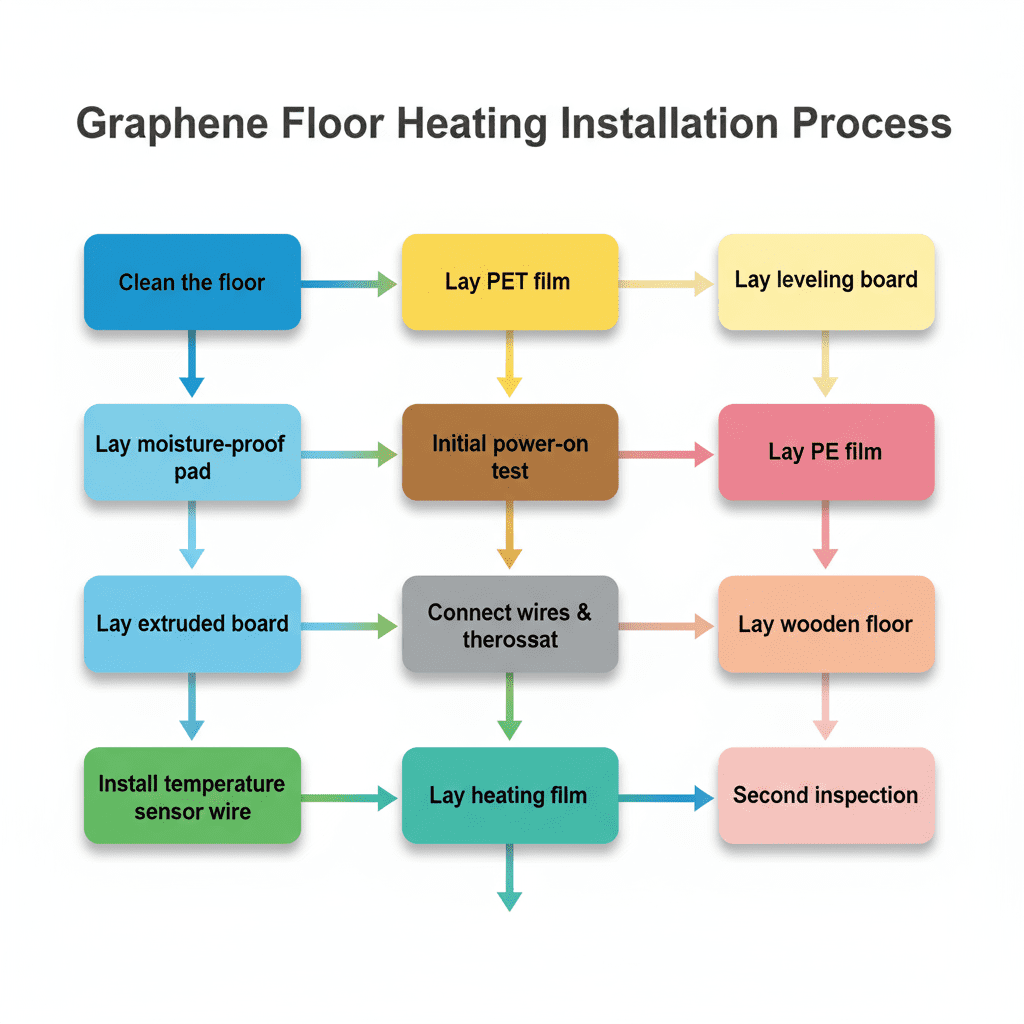

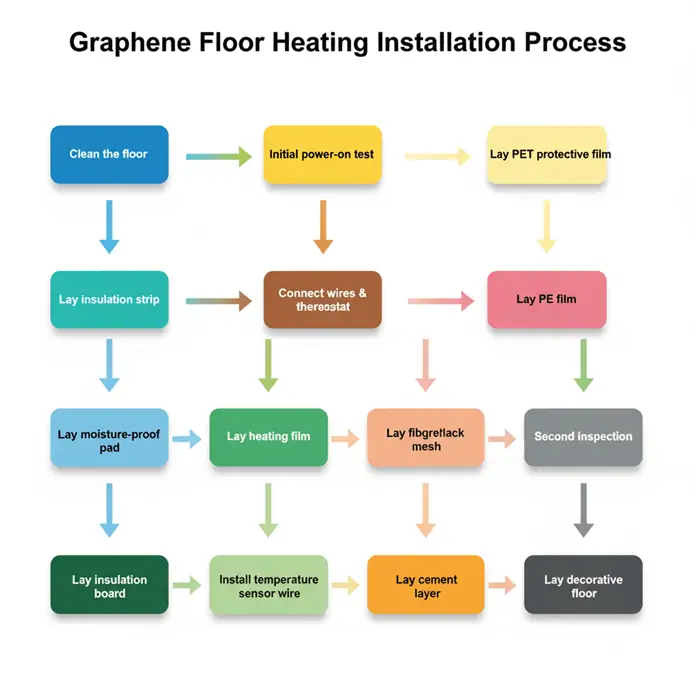

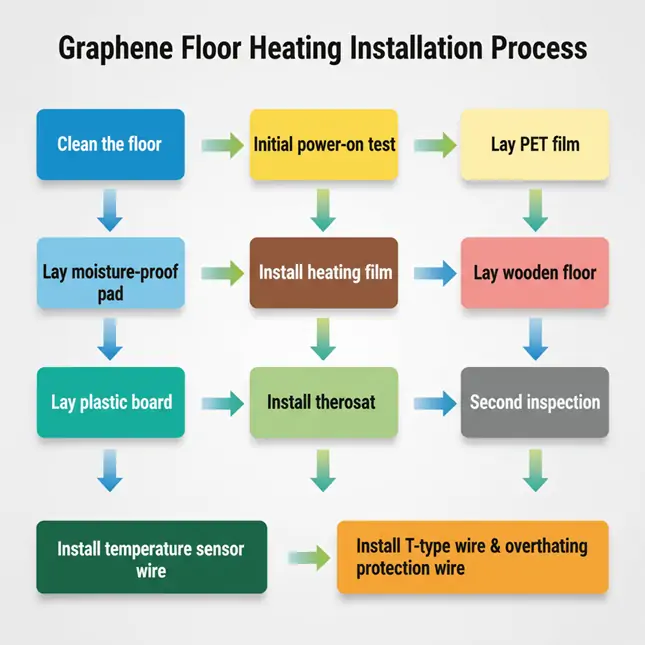

One of the most compelling advantages of graphene heating film lies in its remarkable versatility in application methods. Unlike traditional heating systems that require extensive structural modifications or specialized installation procedures, graphene electric heating film can be seamlessly integrated into virtually any building project. The installation process resembles applying regular paint, making it accessible to both professional contractors and DIY enthusiasts.

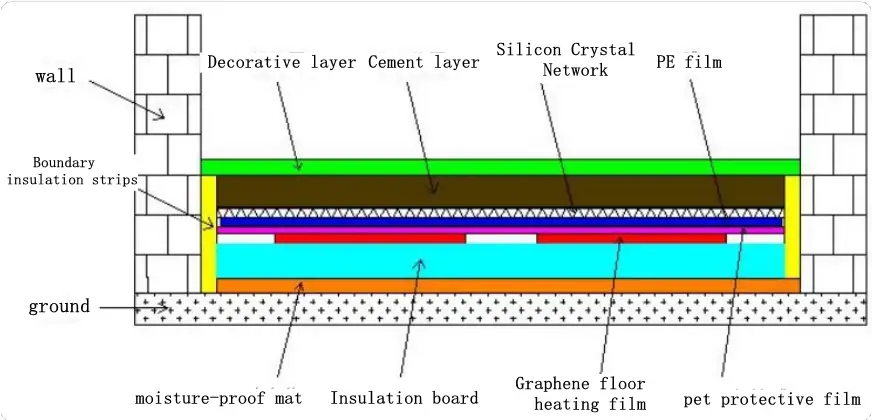

This innovative heating technology can be applied to common building materials including concrete, cement layers, wooden substrates, and various floor finishes. The graphene film integrates directly into the building structure, whether buried in cement layers or installed beneath floor coverings. This flexibility eliminates the need for complex ductwork or bulky radiator systems that traditional heating methods require.

The material compatibility extends to multiple flooring options, with stone, imitation stone, and ceramic tiles offering the best thermal conductivity performance. These materials not only maximize heat transfer efficiency but also provide dual functionality – delivering warmth in winter while helping to lower indoor temperatures during summer months. For those preferring wood finishes, waterproof and heat-resistant composite flooring and bamboo flooring also demonstrate excellent thermal conductivity properties.

Perfect for new construction and renovation projects

Now that we have covered the application versatility, graphene heating film proves equally suitable for both new construction and renovation projects. For newly built residential buildings, the system integrates seamlessly during the construction phase, allowing builders to incorporate the heating film directly into the foundation or floor structure before applying decorative finishes.

The installation timeline considerations are particularly important for new construction projects. After system installation completion and ground decoration finishing, the structure requires approximately 28 days of natural drying time before initial heating operation. This curing period ensures optimal performance and longevity of both the heating system and building materials.

During renovation projects, the graphene heating film offers significant advantages over traditional heating system upgrades. The thin profile and flexible installation methods minimize disruption to existing structures while providing comprehensive heating coverage. Property owners can retrofit their homes without major demolition or reconstruction work, making it an ideal solution for modernizing older buildings with energy-efficient heating technology.

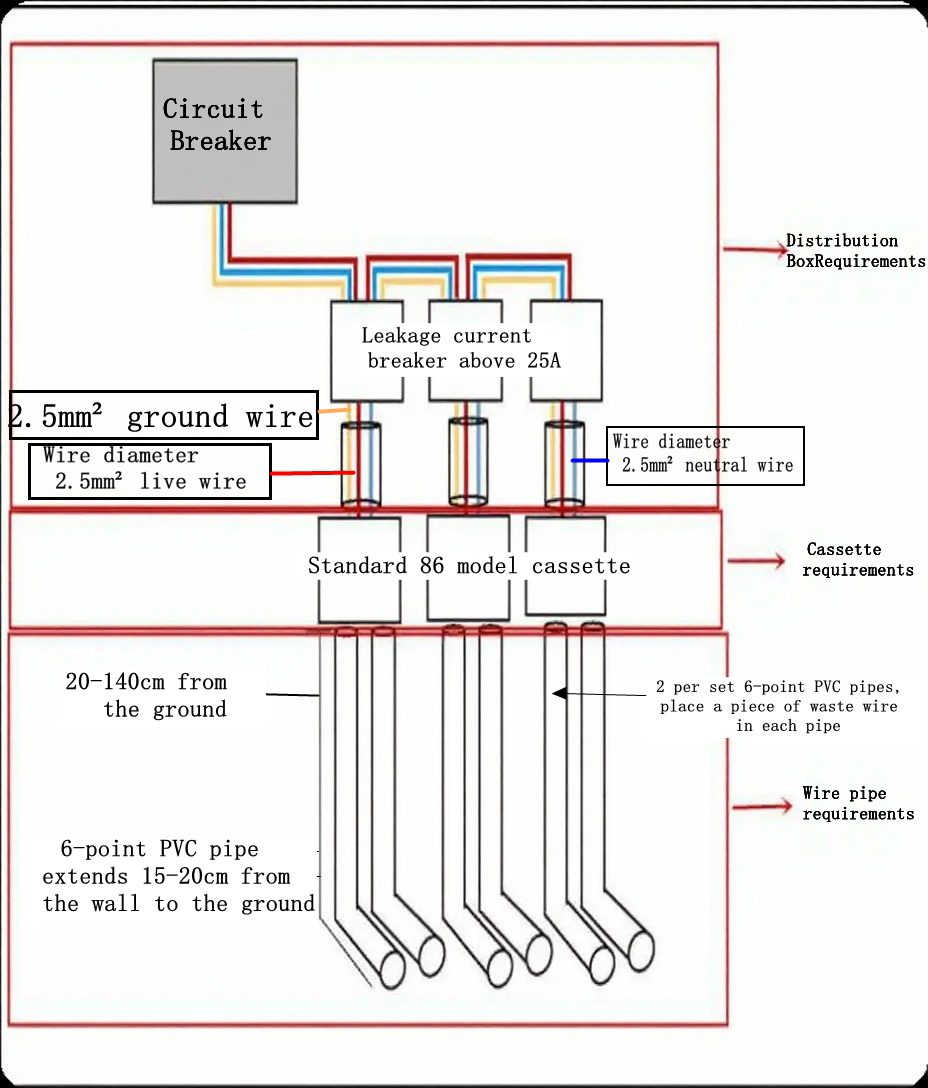

Professional installers must confirm that existing power supply lines and meter capacity can adequately support the system’s electrical load requirements. In cases where current electrical infrastructure proves insufficient, capacity upgrades become necessary to ensure safe and efficient operation.

Ideal solution for bathrooms, kitchens, and moisture-prone areas

Previously, I’ve mentioned the general application benefits, but graphene heating film particularly excels in moisture-prone environments where traditional heating systems often struggle. Bathrooms and kitchens present unique challenges for heating systems due to high humidity levels, temperature fluctuations, and potential water exposure.

The graphene heating technology demonstrates superior performance in these demanding environments. When properly installed beneath appropriate flooring materials, the system maintains consistent heating performance despite moisture exposure. The film’s integration into the floor structure provides protection from direct water contact while delivering efficient radiant heat throughout the space.

Special considerations apply when using the heating system in water-containing areas. When leaving properties unoccupied for extended periods, it’s crucial not to completely shut down the system in rooms with water supply and drainage infrastructure. Instead, maintaining room temperatures around 5°C prevents water pipe freezing and potential cracking damage, ensuring both system longevity and property protection.

For optimal performance in moisture-prone areas, stone, ceramic tiles, or other waterproof materials with excellent thermal conductivity should be selected as floor finishes. These materials not only withstand moisture exposure but also maximize the heating system’s efficiency, creating comfortable and safe environments in bathrooms, kitchens, and similar high-moisture spaces.

The installation flexibility allows for precise temperature control in these areas through properly configured thermostats, ensuring comfort while maintaining energy efficiency even in the most challenging indoor environments.

Long-Term Durability and Performance Benefits

Withstands extreme temperatures up to 180°C operating conditions

Graphene heating film demonstrates exceptional thermal resilience, making it ideal for demanding home heating applications. The material’s inherent stability allows these graphene heating panels to function effectively under extreme temperature conditions without compromising performance or safety. This remarkable temperature tolerance ensures that graphene home heating systems maintain consistent operation even during peak heating demands or in challenging environmental conditions.

The superior thermal properties of graphene enable uniform heat distribution across the entire surface area, eliminating the hot spots and temperature variations common in conventional heating elements. This characteristic makes infrared heating systems using graphene technology particularly reliable for long-term residential use, as the material’s structure remains stable throughout continuous heating cycles.

Over 300,000 hours of reliable service life

Now that we understand the temperature resilience, the longevity of graphene heating film becomes even more impressive. The durability of graphene ensures that these electric heating solutions deliver extraordinary service life, significantly outperforming traditional heating technologies. Graphene’s resistance to corrosion and physical degradation means that energy efficient heating systems utilizing this technology require minimal maintenance and replacement over their operational lifetime.

This extended service life translates directly into reduced long-term costs for homeowners, as the heating elements maintain their efficiency and performance characteristics throughout their lifespan. The material’s chemical stability prevents the deterioration commonly seen in conventional heating elements, ensuring that modern home heating systems powered by graphene technology continue operating at peak efficiency for decades.

High-pressure resistance up to 1500V for safety assurance

With durability established, safety becomes paramount in graphene heating installation projects. Graphene heating film’s exceptional electrical properties provide robust high-voltage resistance, ensuring safe operation in residential environments. This electrical stability, combined with the material’s inherent safety characteristics, makes smart heating technology using graphene suitable for various installation configurations without compromising household safety standards.

The high-pressure resistance feature adds an additional layer of protection, particularly important in radiant heating technology applications where electrical safety is crucial. This safety assurance allows homeowners to confidently integrate graphene heating systems into their properties, knowing that the technology meets stringent electrical safety requirements while delivering superior heating performance.

Environmental and Aesthetic Advantages for Modern Homes

Prevents condensation and mold formation on interior surfaces

Modern graphene heating film systems operate at optimal surface temperatures that eliminate the conditions conducive to condensation and mold growth on interior walls and surfaces. Unlike traditional heating methods that create temperature variations and cold spots, graphene heating panels provide uniform radiant heat distribution across entire wall surfaces. This consistent heating prevents the temperature differentials that typically lead to moisture accumulation on interior surfaces.

The radiant heating technology inherent in graphene systems warms surfaces directly rather than just the air, maintaining wall temperatures above the dew point throughout heating cycles. This fundamental approach to heat distribution ensures that interior surfaces remain dry and inhospitable to mold spores, contributing to healthier indoor air quality and reducing maintenance requirements for homeowners.

Complete design freedom with no visible heating units

With this understanding of graphene’s performance benefits, the aesthetic advantages become equally compelling for modern home design. Graphene heating films can be installed beneath flooring materials, behind wall finishes, or within ceiling structures, completely eliminating visible heating equipment from living spaces. This invisible installation approach provides architects and interior designers with unprecedented freedom to create clean, unobstructed room layouts.

The ultra-thin profile of graphene heating panels allows integration into virtually any surface without affecting room dimensions or design aesthetics. Homeowners can achieve seamless interior spaces without the visual interruption of traditional radiators, baseboard heaters, or HVAC vents, enabling furniture placement and room design based purely on functional and aesthetic preferences rather than heating system constraints.

Supports decarbonization and sustainable building goals

Now that we have covered the practical advantages, the environmental benefits of graphene heating technology align perfectly with contemporary sustainability objectives. Recent research demonstrates that graphene production through flash Joule heating from biomass waste materials can achieve more than 90% reduction in carbon emissions and freshwater use compared to conventional graphene manufacturing processes.

This breakthrough in sustainable graphene production means that energy efficient heating systems utilizing graphene heating film can contribute significantly to building decarbonization initiatives. The material’s exceptional thermal conductivity enables lower energy consumption for space heating, while its production from renewable biomass waste sources creates a circular economy approach to manufacturing.

The carbon-neutral potential of biomass-derived graphene, combined with the system’s operational efficiency, supports green building certifications and sustainable construction goals. Modern home heating installations using graphene technology can help property owners meet increasingly stringent environmental regulations while reducing long-term carbon footprints associated with residential heating requirements.

Graphene film represents a paradigm shift in home heating technology, offering an unprecedented combination of energy efficiency, comfort, and versatility. With laboratory-tested energy savings of up to 40% compared to traditional electric radiators and thermal conversion rates exceeding 99%, this revolutionary technology delivers both environmental benefits and significant cost reductions. The system’s silent operation, uniform heat distribution through far-infrared radiation, and maintenance-free design make it an ideal solution for modern homes seeking superior comfort without compromising aesthetics.

The future of home heating is here, and it’s as simple as applying paint to your walls. Whether you’re building new construction or renovating existing spaces, graphene heating film offers the flexibility to transform any room into an efficiently heated environment. With its ability to prevent condensation and mold while providing designers complete aesthetic freedom, this technology isn’t just an upgrade—it’s a smart investment in your home’s comfort, value, and sustainability for decades to come.