Revolutionizing Home and Commercial Heating with Advanced Graphene Technology

Winter heating bills don’t have to drain your bank account. At Changzhou 2D Carbon Tech Co., Ltd., we’ve developed graphene underfloor heating systems that slash energy costs while keeping your spaces perfectly comfortable. Our cutting-edge technology delivers the warmth you need with up to 70% less energy consumption than traditional heating methods.

Who This Is For: Homeowners seeking lower energy bills, architects designing sustainable buildings, and interior designers creating comfortable modern spaces will discover how graphene heating transforms any environment into an energy-efficient haven.

Traditional heating systems waste energy through uneven heat distribution and high power consumption. Our graphene-based solution changes everything. The exceptional heat conductivity of graphene creates faster, more uniform warmth that spreads evenly across your floors, eliminating cold spots and reducing energy waste.

What You’ll Learn: We’ll explore how graphene heating technology works at the molecular level, compare real-world energy savings against conventional systems, and showcase practical applications from cozy family homes to large commercial buildings. You’ll see exactly why leading architects and designers are choosing sustainable heating solutions that benefit both budgets and the environment.

Get ready to discover why graphene underfloor heating represents the future of energy efficient heating – and how it can transform your next project into a model of comfort and sustainability.

Meet Changzhou 2D Carbon Tech Co., Ltd.: Pioneers in Graphene Heating Innovation

Company mission and commitment to practical, affordable heating solutions

2D Carbon Graphene Material Co., Ltd. stands at the forefront of graphene heating systems innovation, transforming how we approach modern heating solutions. Established in December 2011 with a substantial registered capital of 30 million RMB, our company has dedicated over a decade to perfecting the science of graphene technology applications. Our mission centers on making advanced graphene underfloor heating technology both practical and accessible to homeowners, architects, and commercial developers seeking energy efficient heating solutions.

What sets us apart is our unwavering commitment to bridging the gap between cutting-edge materials science and real-world heating applications. We recognize that revolutionary technology means nothing if it remains confined to laboratories. That’s why 2D Carbon has invested heavily in mass-production capabilities, ensuring that our sustainable heating solutions can reach markets at competitive price points without compromising quality or performance.

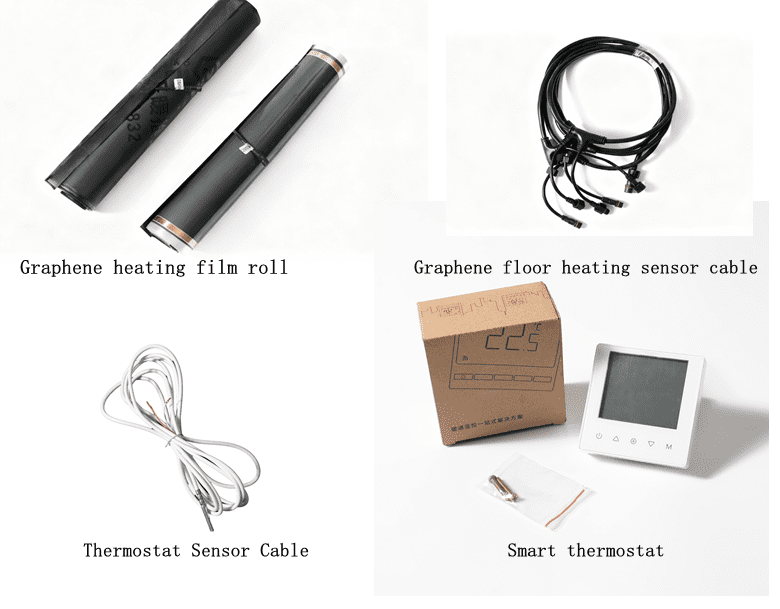

Flagship product: Advanced graphene-based underfloor heating systems

Our expertise in large-scale graphene transparent conductive film production has naturally evolved into developing sophisticated carbon heating systems that redefine comfort and efficiency. 2D Carbon’s flagship graphene-based underfloor heating systems represent the convergence of advanced materials science and practical heating engineering.

These innovative radiant floor heating systems leverage our proprietary graphene transparent conductive film technology, which has been refined through years of research and development. The same precision that goes into producing our transparent electrode materials now powers heating solutions that deliver consistent, uniform warmth throughout residential and commercial spaces. Our electric underfloor heating systems integrate seamlessly into modern construction projects, offering architects and designers unprecedented flexibility in creating comfortable, energy-conscious environments.

Strategic partnerships driving market development

2D Carbon’s growth trajectory is accelerated through strategic partnerships that expand our reach and enhance our technological capabilities. Located at No. 6 Xiangyun Road in the Wujin Economical Development Zone of Changzhou, Jiangsu, our facility serves as a hub for collaboration with industry leaders, research institutions, and distribution partners across global markets.

These partnerships enable us to continuously refine our eco-friendly heating technology while ensuring our products meet diverse regional requirements and building standards. Through collaborative research and development initiatives, we’re constantly pushing the boundaries of what’s possible with graphene heating benefits, from improving energy efficiency metrics to enhancing installation methodologies that make adoption easier for contractors and end-users alike.

Understanding Graphene Heating Technology: The Science Behind Superior Warmth

Exceptional heat conductivity properties of graphene materials

Graphene heating systems leverage the remarkable thermal properties of this revolutionary two-dimensional material. Composed of a single layer of carbon atoms arranged in a honeycomb lattice, graphene represents the first truly two-dimensional material ever created by humans. This unique atomic structure grants graphene exceptional heat conductivity capabilities that form the foundation of our advanced underfloor heating technology.

The thermal conductivity of graphene has been the subject of extensive scientific research. While early estimates suggested thermal conductivity values exceeding 5,000 watts per meter per Kelvin (W/m·K), more refined measurements indicate that graphene maintains a thermal conductivity of approximately 1,300 W/m·K at room temperature. This places graphene among the top-performing heat conducting materials available, making it ideal for efficient heat distribution in residential and commercial heating applications.

What makes graphene particularly effective for heating systems is its ability to transfer heat rapidly and uniformly across its surface. The material’s unique quantum-mechanical properties enable efficient phonon transport – the microscopic mechanism by which heat moves through solid materials. This translates directly into superior performance for graphene heating systems, ensuring consistent warmth distribution throughout your space.

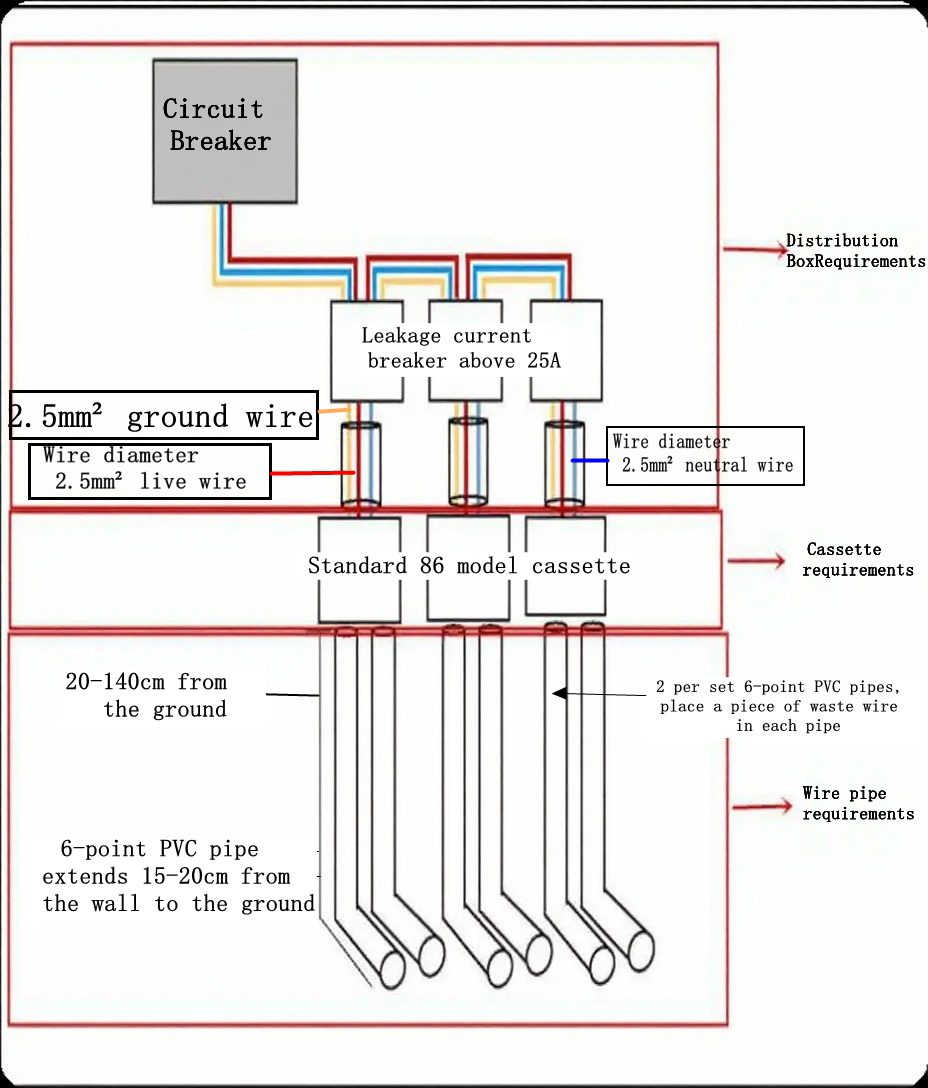

Low voltage system design for enhanced safety and efficiency

Our graphene underfloor heating systems operate on carefully engineered low voltage principles, prioritizing both safety and energy efficiency. Unlike traditional heating methods that require high voltage electricity, graphene heating technology functions effectively at significantly reduced voltage levels, typically operating between 12-24 volts.

This low voltage design offers multiple advantages for modern heating applications. The reduced electrical requirements translate directly into enhanced safety for homeowners, architects, and building occupants. Lower voltage systems minimize electrical hazards, making installation and maintenance safer processes while reducing the risk of electrical accidents.

From an efficiency standpoint, the low voltage operation of graphene heating systems contributes to their exceptional energy performance. The material’s superior thermal conductivity means that less electrical energy is required to achieve the same heating output compared to conventional heating methods. This efficiency gain is particularly pronounced in underfloor heating applications, where the large surface area of graphene heating elements can distribute warmth evenly across entire room spaces.

The electrical efficiency of our graphene heating systems also contributes to reduced energy consumption and lower utility costs. By converting electrical energy to heat more effectively than traditional heating elements, these systems can maintain comfortable temperatures while drawing less power from the electrical grid.

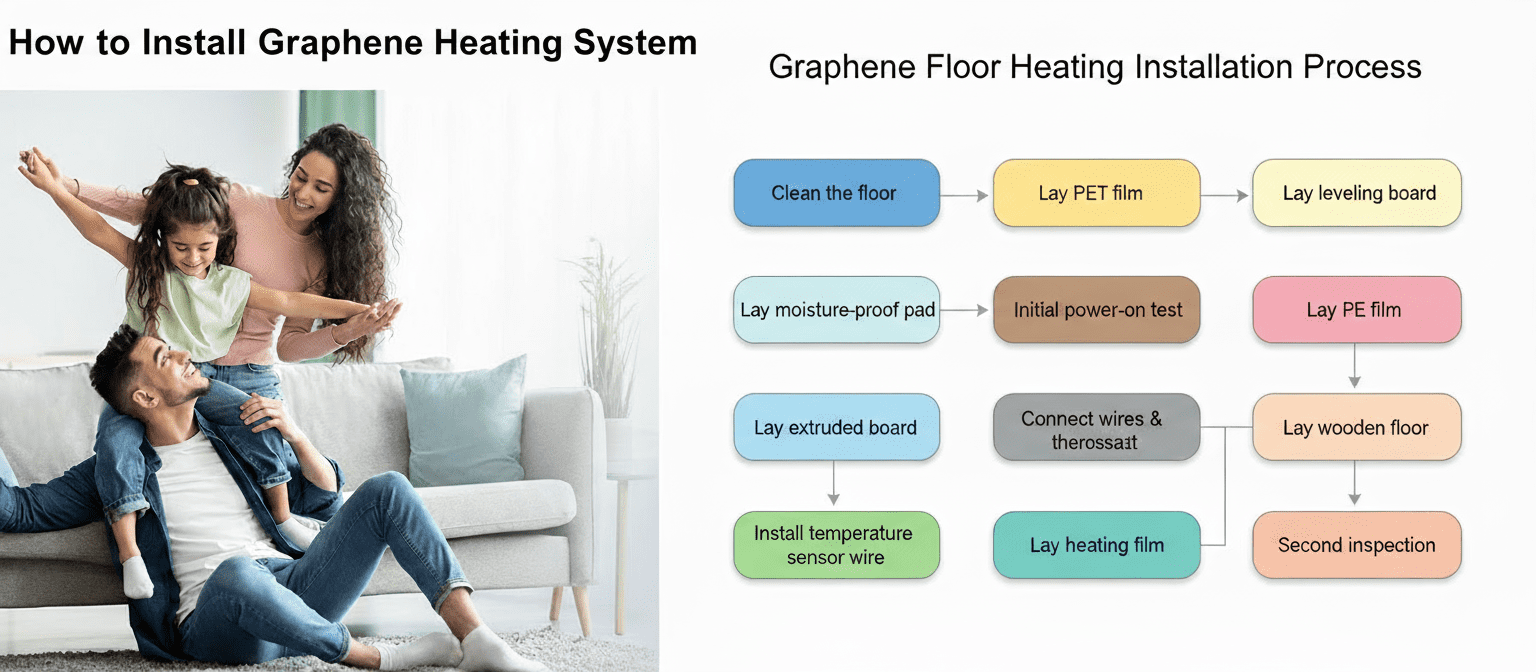

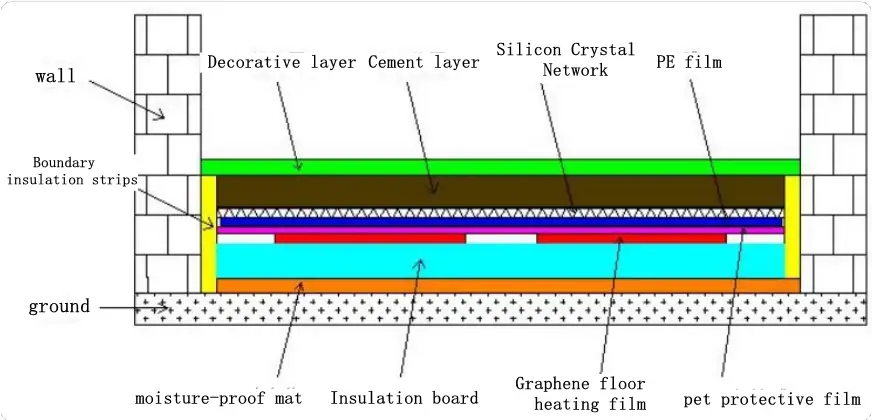

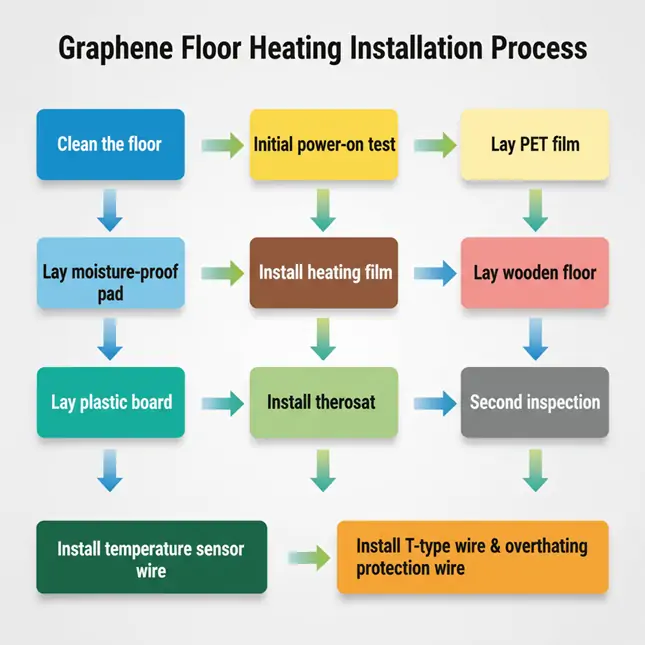

Integration with pre-cut flooring panels for seamless installation

Our graphene heating technology has been specifically designed to integrate seamlessly with pre-cut flooring panels, revolutionizing the installation process for both residential and commercial applications. This innovative approach eliminates many of the traditional complications associated with underfloor heating installation.

The pre-cut flooring panel system allows for precise placement of graphene heating elements within the floor structure. Each panel is engineered to accommodate the specific dimensions and thermal requirements of the graphene heating system, ensuring optimal heat distribution and system performance. This design approach significantly reduces installation time and complexity compared to traditional radiant floor heating systems.

The integration process involves embedding the graphene heating elements directly into the flooring panels during manufacturing. This factory integration ensures consistent quality control and optimal positioning of heating elements for maximum efficiency. The result is a complete heating solution that can be installed as easily as standard flooring materials, without the need for specialized heating system installation.

This seamless integration approach makes graphene underfloor heating accessible to a broader range of applications, from new construction projects to retrofit installations in existing buildings. The pre-cut design accommodates various flooring types and room configurations, providing architects and interior designers with flexible heating solutions that don’t compromise aesthetic or functional requirements.

Energy Efficiency and Cost Savings: Revolutionizing Heating Economics

Up to 70% Energy Consumption Reduction vs Traditional Copper Wire Systems

Our graphene heating systems deliver unprecedented energy efficiency that revolutionizes heating economics for modern spaces. Through advanced materials science, our technology achieves energy consumption reductions of up to 70% compared to traditional copper wire systems, setting a new standard for energy efficient heating solutions.

The remarkable efficiency stems from graphene’s unique properties as a heating element. Unlike conventional systems that waste energy heating multiple materials—such as heating water to heat radiators which then heat air—our graphene heating systems deliver heat directly where it’s needed. This direct heating approach eliminates the energy losses inherent in traditional multi-stage heating processes.

Laboratory testing has validated our system’s superior performance metrics, with average energy consumption of just 35 W/m². The graphene underfloor heating technology takes advantage of graphene’s minimal thermal mass, allowing for instant on/off response and eliminating the energy waste associated with heating up the heater itself. This precision control, combined with graphene’s large surface area, ensures maximum efficiency in converting electricity to usable heat.

Significantly Lower Running Costs Compared to Conventional Underfloor Heating

When compared to conventional underfloor heating systems, our sustainable heating solutions demonstrate substantial cost advantages that benefit both residential and commercial applications. The 40% reduction in energy consumption compared to traditional radiators translates directly into lower monthly utility bills for property owners.

Our electric underfloor heating system’s efficiency rivals that of heat pumps while offering superior installation flexibility and maintenance-free operation. The combination of reduced energy consumption and elimination of complex mechanical components results in dramatically lower operational costs over the system’s lifetime.

The instant heating response enabled by graphene’s properties allows for sophisticated control algorithms that learn user behavior patterns and optimize heating schedules automatically. This smart switching capability ensures energy is only consumed when and where heating is actually needed, further reducing running costs compared to systems that maintain constant temperatures throughout spaces.

Long-term Financial Benefits for Homeowners and Businesses

The economic advantages of our graphene heating technology extend far beyond immediate energy savings, creating compelling long-term value propositions for property owners. The maintenance-free nature of our systems eliminates the ongoing costs associated with traditional heating infrastructure, including regular servicing, component replacements, and system repairs.

For businesses, the modular design and compatibility with various building materials reduce installation complexity and associated labor costs. The absence of pipes, mechanical units, and complex distribution systems means lower initial installation expenses and reduced risk of costly failures or leaks that plague conventional heating systems.

Property owners also benefit from enhanced space utilization, as our carbon heating systems eliminate the need for radiators and bulky heating equipment, increasing usable floor space and providing architects and designers with greater flexibility. This space optimization can translate into higher property values and rental income potential for commercial applications.

The durability and longevity of graphene-based heating elements ensure stable heating costs over decades, protecting property owners from the inflation of maintenance and replacement costs that affect traditional heating systems. Additionally, the eco-friendly heating technology positions properties favorably in markets increasingly focused on sustainability and energy efficiency ratings.

Superior Performance: Uniform Heat Distribution and Comfort

Faster, More Efficient Warmth Distribution Throughout Spaces

Graphene-based underfloor heating systems excel at delivering rapid and efficient warmth distribution through their unique thermal properties. Unlike traditional convection heating systems that warm the ambient air first, graphene heating films emit far-infrared radiation that heats people and objects directly, providing an effect similar to the warmth of the sun.

The exceptional thermal conductivity of graphene enables faster temperature rise compared to conventional heating methods. This innovative technology ensures that spaces reach desired temperatures more quickly, reducing the time needed to achieve optimal comfort levels. The graphene heating films integrate seamlessly under various floor coverings including tiles, parquet, and carpet, creating an invisible yet highly effective heating solution.

Consistent Temperature Control for Optimal Comfort

The superior performance of graphene heating technology lies in its ability to maintain uniform temperature distribution throughout heated spaces. Rather than creating hot and cold spots common with traditional heating systems, graphene heating films provide gentle, even heat distribution that eliminates thermal gradients between floor and ceiling.

This consistent heating approach significantly reduces the temperature variations that often occur with conventional heating methods. The infrared radiation technology limits temperature gradients while preserving air quality by reducing convection movements, which can stir up dust and allergens. Users experience increased thermal comfort naturally, which instinctively encourages them to turn down the thermostat, resulting in energy savings of up to 30%.

The responsive nature of graphene heating allows for precise temperature management, adapting to real user needs through intelligent control systems. This smart temperature management prevents energy waste while maximizing comfort levels across different zones within a space.

Enhanced Heating Performance in Both Residential and Commercial Applications

Graphene underfloor heating systems demonstrate exceptional versatility across various applications, from residential homes to commercial spaces and specialized environments. In residential settings, the technology provides ideal thermal comfort under different flooring materials while maintaining energy efficiency throughout daily use cycles.

Commercial applications benefit from the stable, uniform heating characteristics that graphene technology provides. The systems perform consistently across large spaces, making them particularly suitable for offices, retail environments, and public buildings where maintaining comfortable temperatures is crucial for occupant satisfaction.

The technology has also proven effective in specialized applications such as public transport systems, where graphene heating foils provide stable heating in trains and other vehicles. The thermal radiation characteristics help maintain comfortable conditions while minimizing energy consumption, making them ideal for environments where consistent performance and energy efficiency are paramount.

The lightweight, thin, and flexible nature of graphene heating films allows for easy integration into different products and environments, providing architects and designers with greater flexibility in creating comfortable spaces without compromising on aesthetic or functional requirements.

Environmental Benefits: Sustainable Heating for a Greener Future

Reduced carbon footprint through lower energy consumption

Changzhou 2D Carbon Tech’s graphene heating systems represent a significant breakthrough in reducing environmental impact through dramatically lower energy consumption. Traditional heating methods, particularly gas boilers, emit over eight and a half times as much nitrogen oxide as all gas power plants combined, with the average electric water heater responsible for roughly three tons of carbon dioxide annually – nearly equivalent to the emissions generated by an average automobile.

Our energy efficient heating technology addresses this critical environmental challenge by delivering up to 80% reduction in kilowatt consumption compared to traditional natural gas and oil heating systems. The exceptional thermal conductivity properties of graphene enable remarkable energy transfer capabilities, meaning our graphene heating systems require significantly less electricity to achieve the same comfort levels as conventional heating solutions.

This dramatic reduction in energy consumption directly translates to a substantially smaller carbon footprint. When buildings integrate our eco-friendly heating technology, they contribute meaningfully to the urgent need for emissions reduction – particularly important considering that household emissions from heating and hot water must decrease by 95% to reach 2050 net-zero targets.

Eco-friendly alternative to traditional heating methods

Our graphene underfloor heating systems offer a compelling eco-friendly alternative to carbon-intensive traditional heating methods that typically rely on fossil fuel burning furnaces. Unlike conventional heating systems that lack efficiency and generate substantial environmental impact, our sustainable heating solutions harness the unique properties of graphene-enhanced materials to deliver superior performance with minimal environmental consequences.

The environmental advantages extend beyond operational efficiency. Preliminary carbon life-cycle assessments demonstrate that graphene-enhanced heating systems can reduce CO2 emissions by up to 44% when compared to existing heating collectors. This remarkable improvement stems from graphene’s ability to enhance thermal conductivity while maintaining durability, chemical resistance, thermal stability, and UV resistance – characteristics that ensure long-term performance without the environmental degradation associated with traditional metal-based heating components.

Furthermore, our carbon heating systems eliminate the complex assembly requirements and susceptibility to corrosion that plague conventional copper and aluminium-based heating systems, reducing maintenance needs and extending system lifespan while minimizing environmental impact throughout the product lifecycle.

Supporting sustainability goals for modern buildings

Modern buildings increasingly require heating solutions that align with ambitious sustainability goals and green building certifications. Our graphene heating benefits directly support these objectives by providing a heating solution that dramatically reduces both energy consumption and environmental impact.

The integration of our radiant floor heating systems enables buildings to achieve significant improvements in their overall environmental performance. The enhanced energy efficiency creates a competitive cost advantage while supporting corporate sustainability initiatives and environmental compliance requirements. Buildings utilizing our technology can demonstrate measurable progress toward carbon neutrality goals while maintaining superior comfort standards.

Our heating systems also support the broader transition toward renewable energy integration. The reduced energy demands of our electric underfloor heating systems make them ideal for pairing with solar panels and other renewable energy sources, creating truly sustainable heating ecosystems that align with green building standards and environmental certifications.

The versatility of graphene-enhanced heating technology positions it as a key component in the global shift toward sustainable building practices, offering architects and developers a proven solution that delivers both environmental benefits and superior performance for modern spaces.

Ideal Applications: Perfect Fit for Modern Spaces

Residential homes seeking energy-efficient heating solutions

Modern homeowners increasingly demand heating systems that deliver both comfort and cost-effectiveness. Graphene underfloor heating emerges as the perfect solution for residential applications, offering up to 40% energy savings compared to traditional electric radiators. This innovative energy efficient heating technology transforms how homes stay warm while reducing environmental impact.

The versatility of graphene heating systems makes them ideal for critical residential areas such as bathrooms, kitchens, and basements. By directly heating interior surfaces, these sustainable heating solutions help prevent condensation and mold formation – common problems in moisture-prone areas. The system’s ability to generate stable thermal distribution without stratification ensures every corner of your home receives consistent warmth.

Installation flexibility sets graphene heating apart for residential use. Whether applied during new construction or home renovations, the technology integrates seamlessly with common building materials from drywall to sandwich panels. Homeowners benefit from the absence of visible radiators or mechanical units, providing complete design freedom for interior spaces while maintaining superior graphene heating benefits.

Commercial spaces requiring reliable, cost-effective warmth

Commercial environments demand heating solutions that balance operational efficiency with long-term cost management. Graphene heating systems excel in office buildings, schools, hospitals, and retail centers by delivering reliable performance with minimal maintenance requirements. The technology’s proven electrical stability and quick response to current variations make it particularly suited for spaces requiring precise temperature control.

The carbon heating systems offer significant advantages for commercial applications through their low power consumption – averaging only 35 W/m² at full capacity while achieving surface temperatures exceeding 110°C. This efficiency translates directly into reduced operating costs and improved bottom-line performance for commercial property owners.

Building-scale simulations demonstrate that graphene systems outperform traditional floor radiant systems powered by heat pumps, showing greater energy efficiency and lower annual energy consumption. The absence of mechanical components eliminates maintenance schedules and reduces long-term operational disruptions – crucial factors for commercial spaces that cannot afford heating system downtime.

New construction and renovation projects

Both new construction and renovation projects benefit tremendously from the adaptability of graphene underfloor heating technology. The system installs like regular paint, adapting perfectly to various substrates including drywall, PVC, and polyurethane sandwich panels. This versatility makes it particularly suitable for modular applications, prefabricated construction, and lightweight, low-inertia building systems.

For renovation projects, electric underfloor heating with graphene technology offers a non-invasive solution that doesn’t require extensive structural modifications. The thin application profile means minimal disruption to existing floor heights or ceiling clearances, making it ideal for historic building renovations or space-constrained projects.

New construction projects can integrate graphene heating from the ground up, maximizing the system’s potential for energy efficiency and design flexibility. The technology aligns perfectly with green building standards and LEED certification requirements, helping developers meet sustainability goals while delivering superior thermal comfort.

The acoustic benefits cannot be overlooked – with no mechanical components, graphene heating systems provide significant improvement in acoustic comfort within indoor spaces. This makes them particularly valuable for residential developments, offices, and educational facilities where noise reduction is a priority consideration.

Competitive Advantages: Why Choose Graphene Over Traditional Methods

Superior energy efficiency compared to conventional systems

Graphene heating systems demonstrate remarkable energy efficiency that sets them apart from traditional heating methods. With an electro-thermal conversion efficiency of up to 95%, graphene-based underfloor heating significantly outperforms conventional alternatives. This exceptional efficiency stems from graphene’s unique atomic structure—a hexagonal lattice of carbon atoms that creates a superhighway for thermal energy with minimal resistance.

In comparison, traditional electric resistance heating systems typically achieve only 70-85% efficiency due to energy losses from resistance in metal coils and uneven heat distribution. Hydronic heating systems perform even less efficiently at 60-75%, losing substantial energy through boilers, pumps, and poorly insulated piping networks.

The practical implications of this efficiency difference translate into significant cost savings. For a 100 m² home in moderate climate conditions, graphene heating systems consume approximately 500 kWh per month during winter, compared to 700 kWh for conventional electric systems and 900 kWh for hydronic systems when accounting for peripheral components like circulation pumps and boilers. Over a ten-year period, this efficiency advantage can save thousands of dollars in energy costs for graphene heating users.

Lower maintenance requirements and longer lifespan

Now that we’ve established the energy efficiency advantages, let’s examine the long-term durability benefits of graphene heating technology. Graphene heating films offer exceptional longevity with lifespans of 30-50 years and minimal maintenance requirements—typically only requiring thermostat controls and periodic system checks.

Traditional heating systems present significantly higher maintenance burdens. Hydronic systems require ongoing maintenance for boiler protection ($100-$300 annually) and potential pipe repairs, with complete system replacement typically needed after 10-15 years. Electric resistance heating mats suffer from shorter lifespans (15-20 years) due to wire degradation, often requiring complete system replacement when failures occur.

The superior durability of graphene stems from its atomic structure and the absence of moving parts or components prone to degradation. Unlike traditional systems that rely on metal heating elements or complex mechanical components, graphene films maintain their thermal conductivity properties over decades without significant performance decline.

Professional installation support and technical expertise

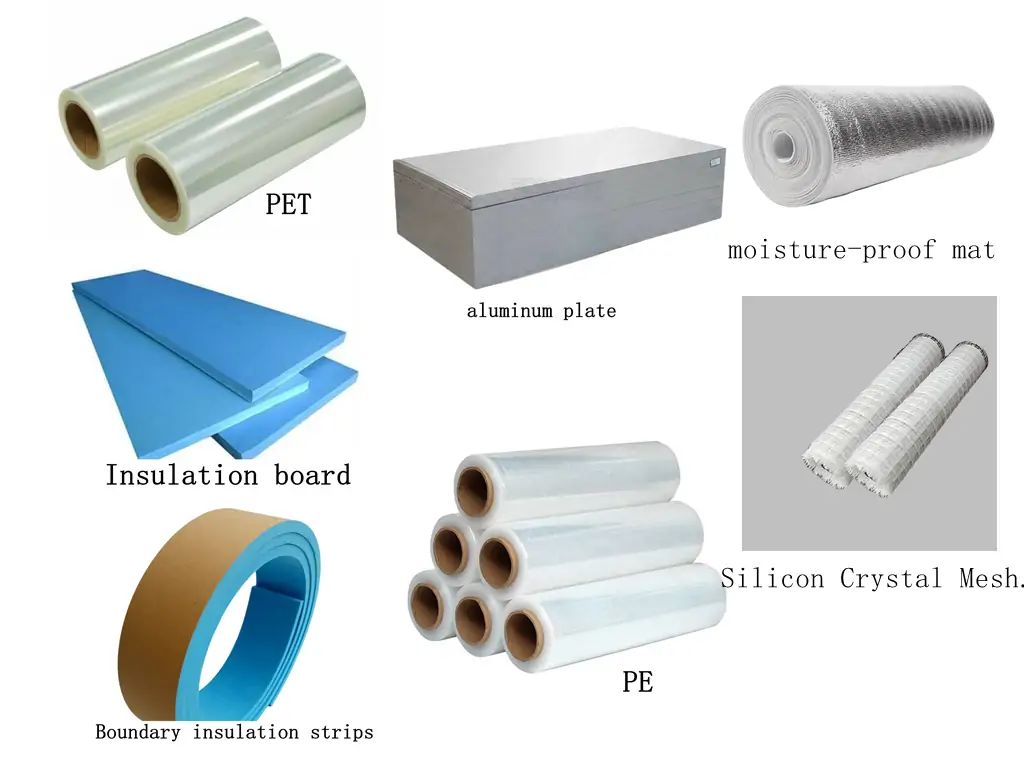

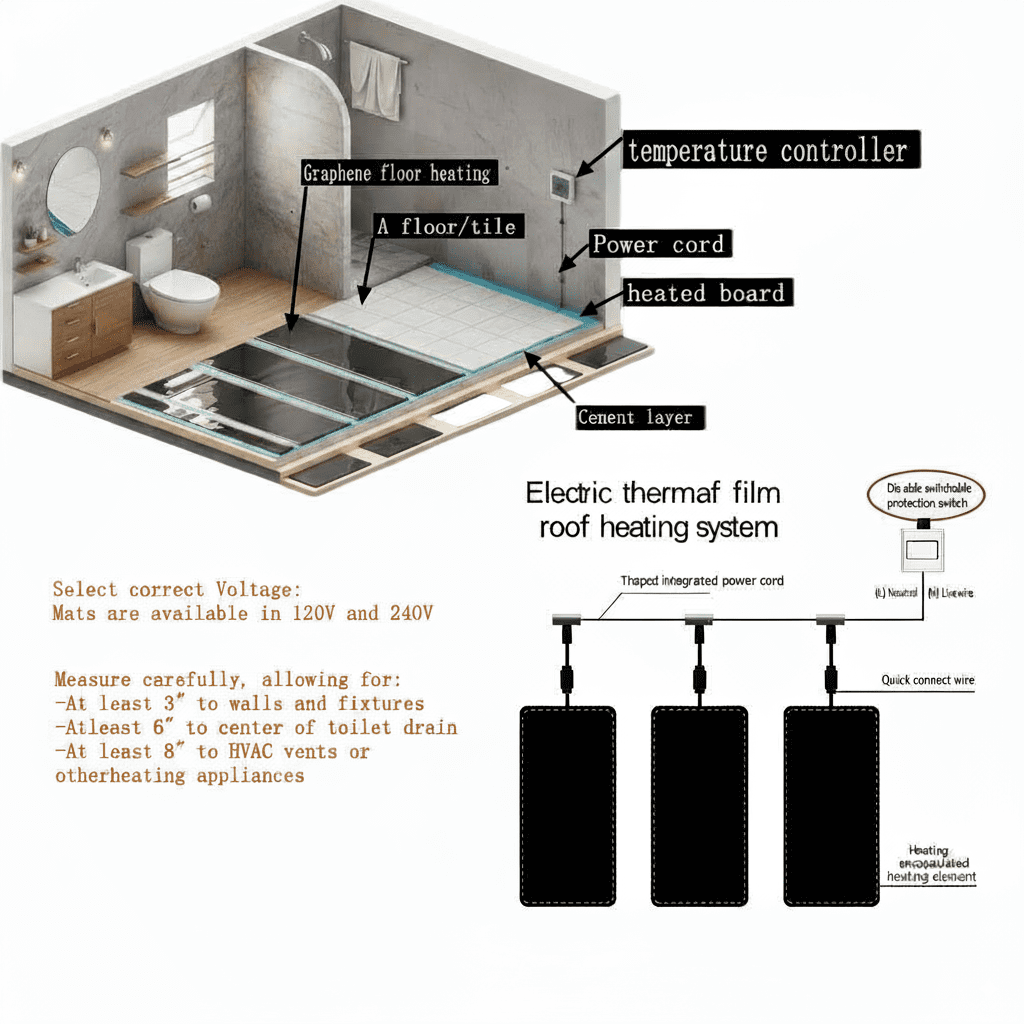

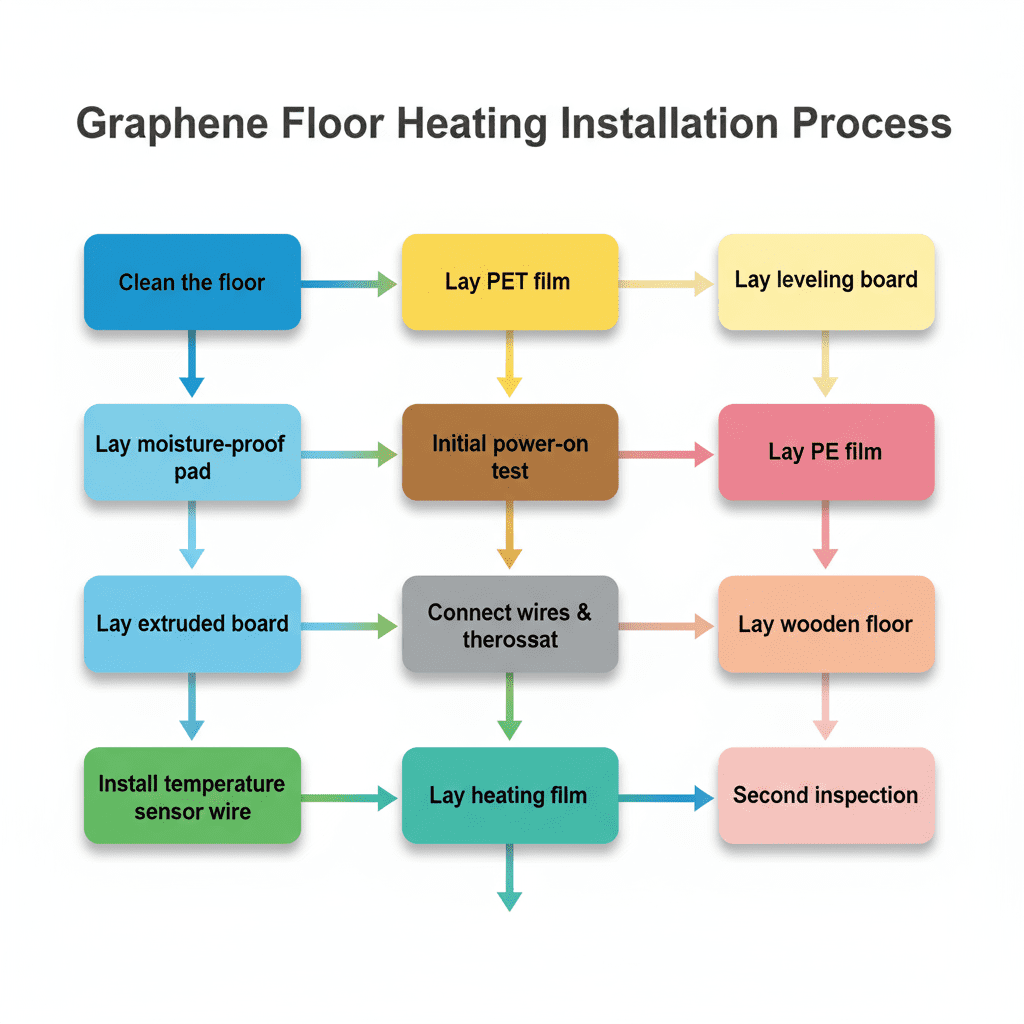

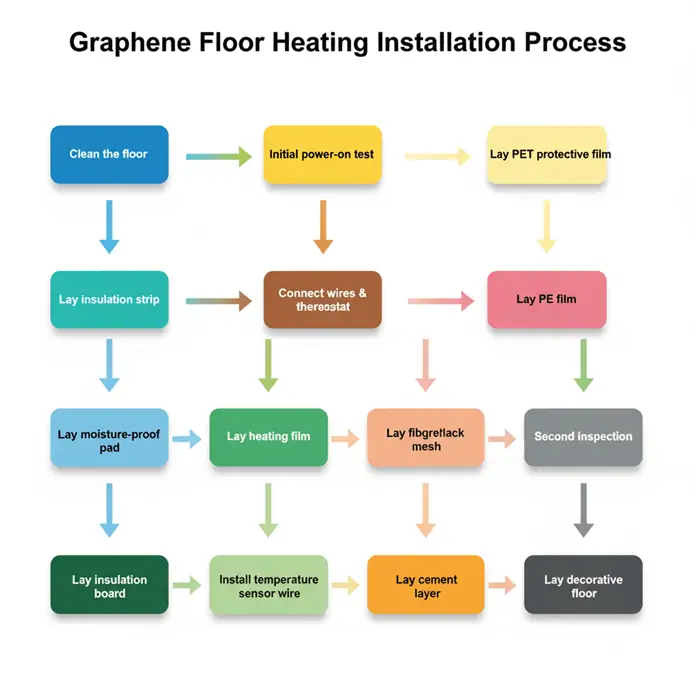

With maintenance advantages clearly established, professional installation becomes a crucial differentiating factor for graphene heating systems. The installation process for graphene underfloor heating is remarkably straightforward compared to conventional methods. Thin films (0.2-0.5 mm) are simply laid over the subfloor, connected to low-voltage electrical supply, and covered with a protective layer such as mortar or subflooring. A 100 m² area can be professionally installed by a small team in 1-2 days.

Traditional systems require significantly more complex installation procedures. Hydronic systems demand pipe laying, boiler connections, pressure testing, and concrete pouring—a 3-5 day process requiring coordination between plumbers and HVAC technicians. Electric resistance mats, while simpler than hydronic systems, still require embedding rigid mats under flooring and maintaining uniform spacing, taking 2-3 days for the same 100 m² area.

The slim profile advantage of graphene heating technology adds only 0.5-1 mm to floor height, making it compatible with all flooring types without requiring subflooring modifications. This architectural flexibility, combined with professional installation support, makes graphene heating ideal for both new construction and renovation projects where space constraints and installation complexity are critical considerations.

As the heating industry evolves toward more sustainable and efficient solutions, Changzhou 2D Carbon Tech Co., Ltd. stands at the forefront of this transformation with our revolutionary graphene-based underfloor heating systems. Our technology delivers unmatched energy efficiency with up to 70% reduction in energy consumption compared to traditional systems, uniform heat distribution for superior comfort, and significant long-term cost savings that make a real difference for homeowners and businesses alike. With proven environmental benefits and exceptional performance, our graphene heating solutions represent the perfect marriage of cutting-edge innovation and practical sustainability for modern spaces.

The future of heating is here, and it’s powered by graphene technology that doesn’t just promise comfort—it delivers measurable results in energy savings, environmental responsibility, and heating performance. Whether you’re a homeowner looking to reduce energy bills, an architect designing sustainable buildings, or an interior designer seeking the most advanced heating solutions for your clients, our graphene underfloor heating systems offer the reliability and efficiency your projects demand. Ready to experience the next generation of heating technology? Contact Changzhou 2D Carbon Tech Co., Ltd. today to learn more about how our innovative graphene heating solutions can transform your space while contributing to a more sustainable future.