Installation De

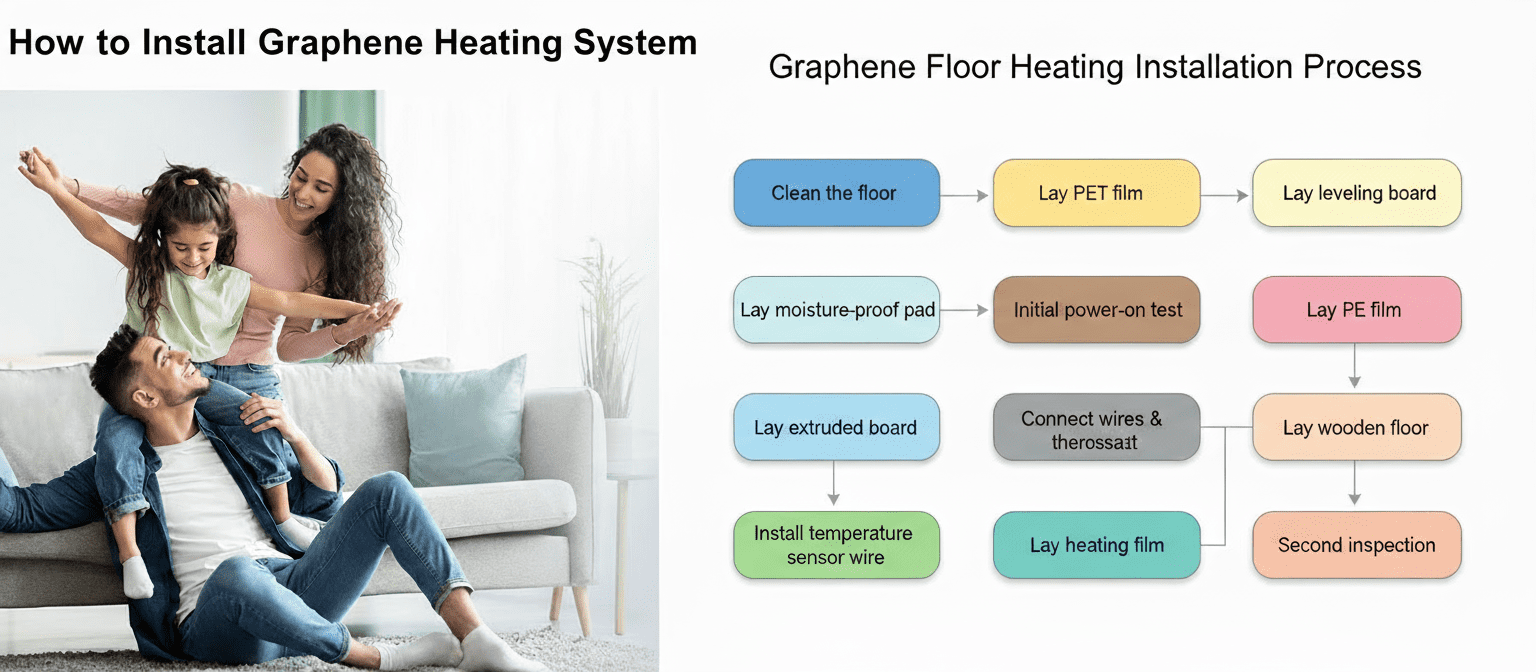

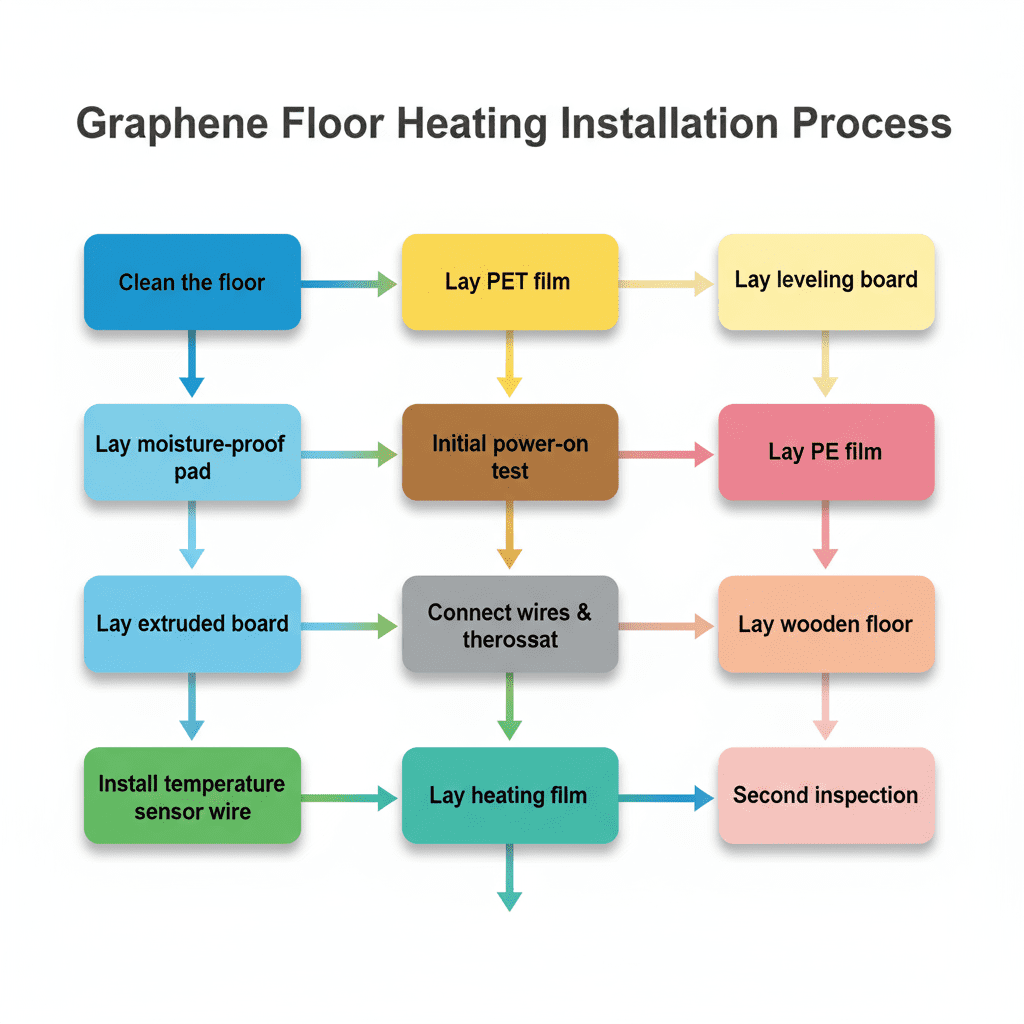

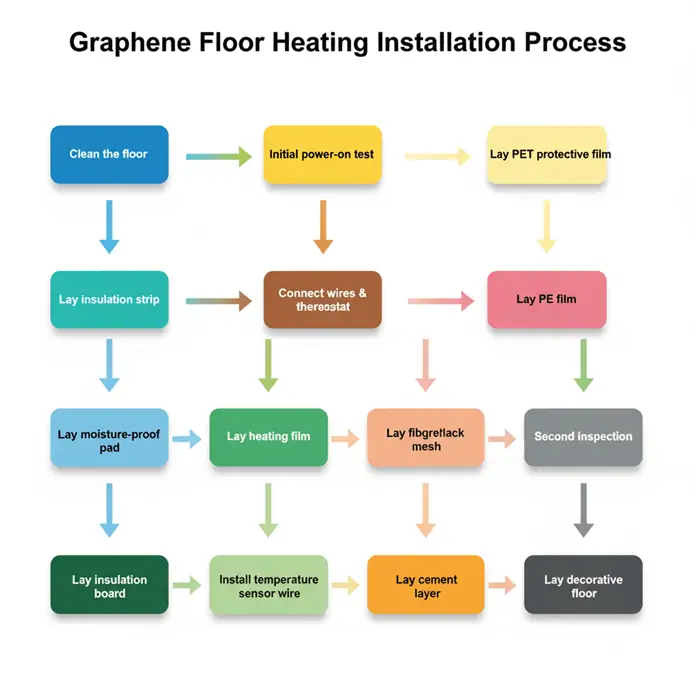

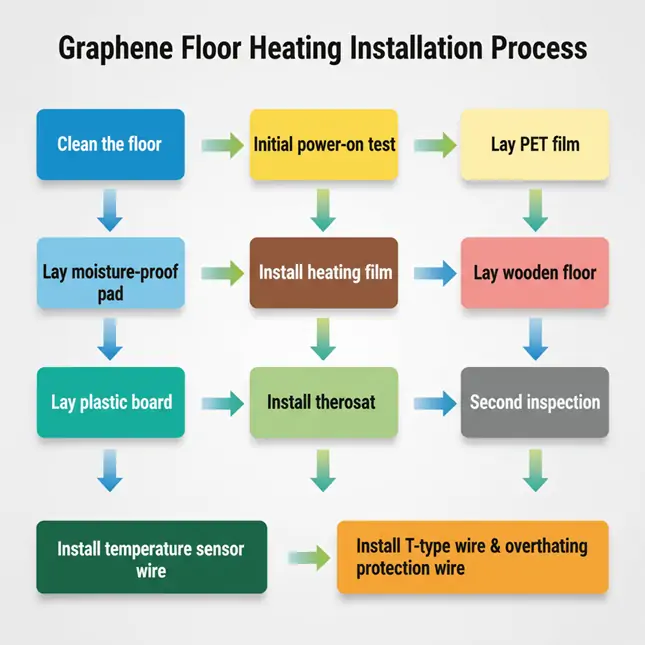

- Clean the Original Ground

Ensure the ground is free of debris and protruding objects. The level difference must be less than 0.4 cm.

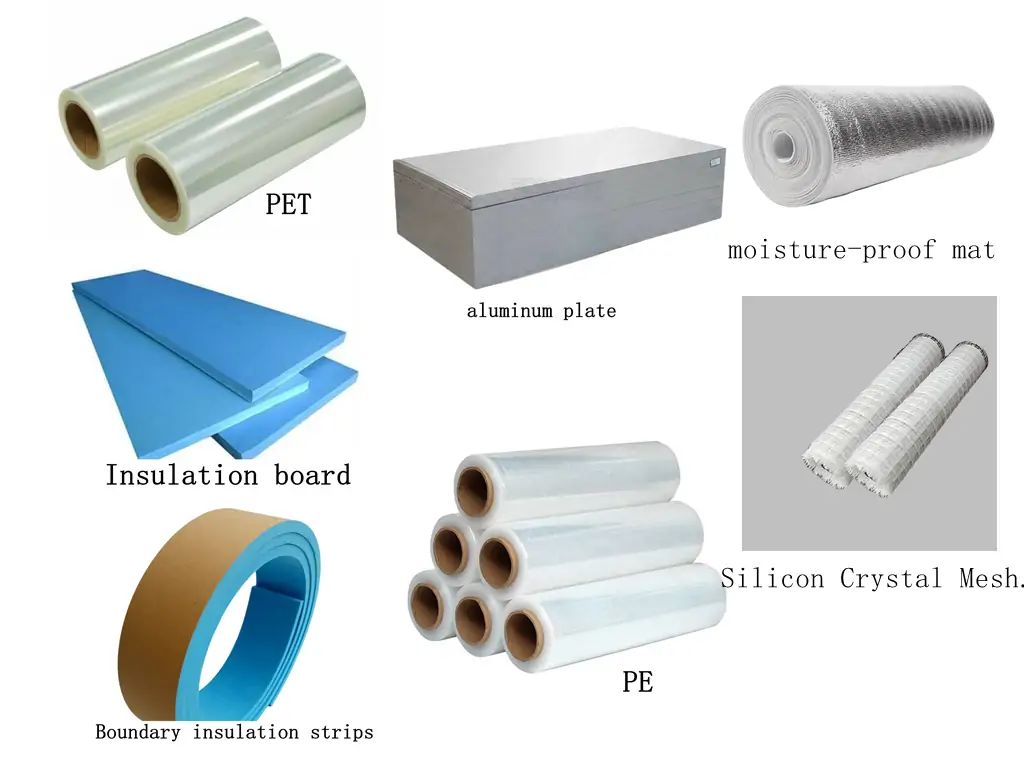

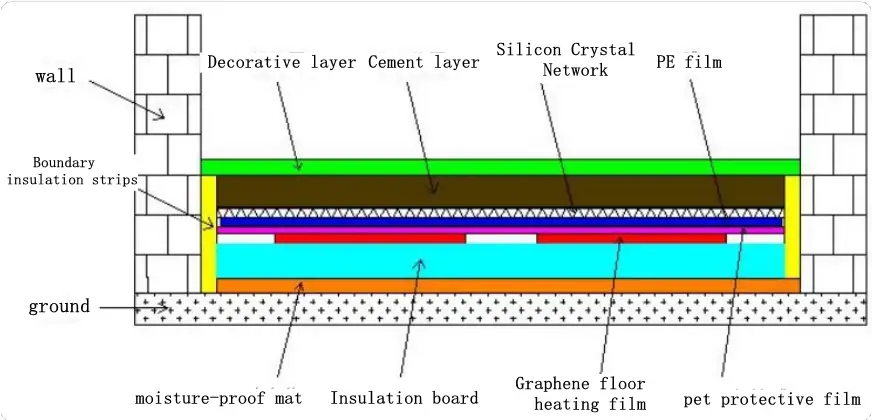

- *Lay Moisture-proof Mat (Conditional)

If the installation is on the ground floor or in an area in contact with soil, a layer of moisture-proof mat must be laid first. The mat should cover the entire room, and the seams should be sealed with tape.

- Lay Insulation Boards (XPS)

Cover the entire room with insulation boards. When laying, the gap between boards should be less than 5mm, and the seams should be sealed with transparent tape. The surface of the boards must be flat; avoid using many small pieces to patch areas. The insulation board thickness should be 20mm. If on the ground floor, the thickness should be increased to 30mm. Leave a 3-5mm expansion gap between the boards and the walls. For larger rooms, leave a 5mm expansion joint every 6 meters.

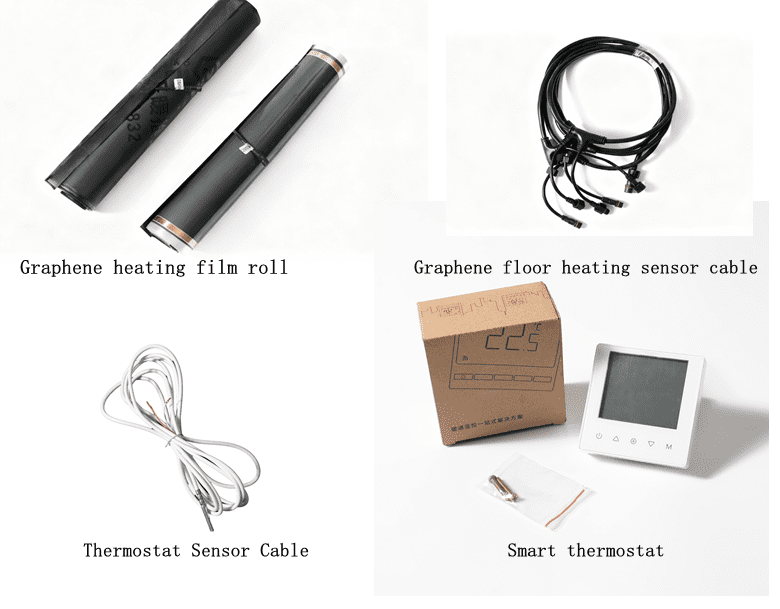

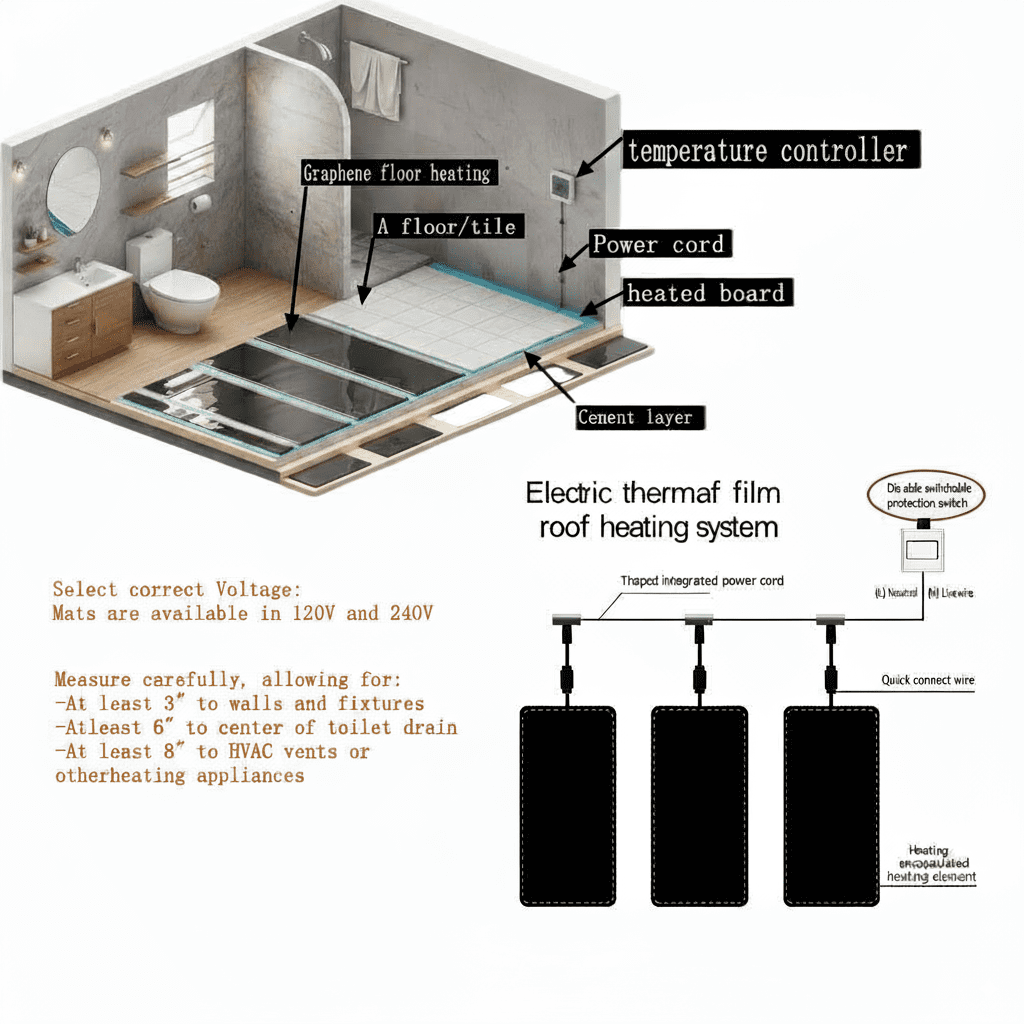

- InstallTemperature Sensor Cable

The connection end of the sensor cable is passed through the conduit and connected to the thermostat. The probe end is placed under the nearest heating film. The position of the heating film is determined by the design drawing. A shallow groove should be cut into the XPS board to house the sensor probe and its wire to prevent the heating film from being uneven.

After placing it, secure the sensor cable with transparent tape.

- Lay the Heating Film

Before laying, sweep the XPS boards to ensure there is no debris or particulate matter on the surface.

Lay the heating film according to the placement and orientation specified in the design drawing. Adjust the spacing between the heating film and the walls, as well as between the film strips. Secure the heating film with tape.

Be careful during installation to prevent tools from damaging the film. Inspect the film after laying.

- Connect Cables and Thermostat

Place the T-shaped cables according to the design drawing and connect them to the heating film. When connecting the male and female connectors, push them in completely and tighten the cap securely.

The T-shaped cable is connected to the thermostat via a connection cable, using male-female connectors.

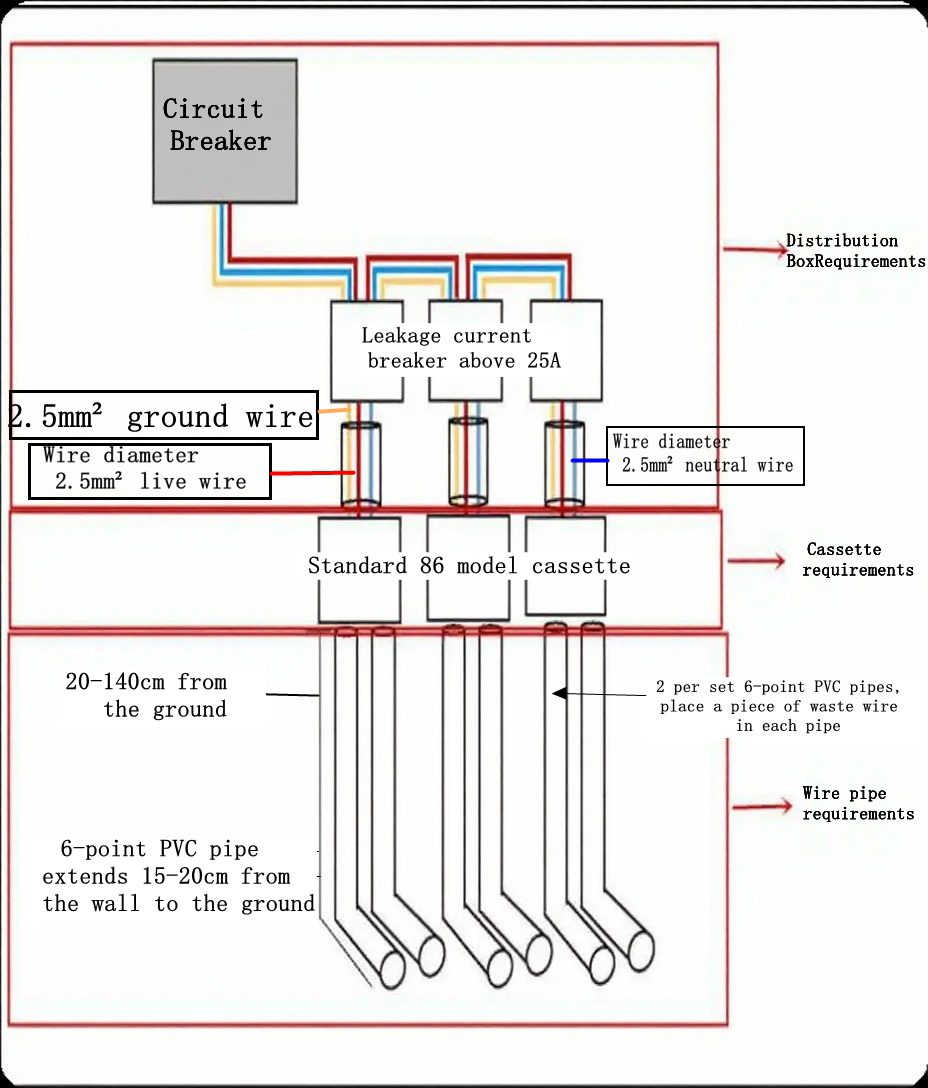

The connection cable is passed through the conduit to the thermostat. When connecting to the thermostat, pay attention to the live and neutral wires (Blue is Neutral, Brown is Live). The same applies when connecting the 220V power supply to the thermostat.

After connecting the cables, use a utility knife or a grooving tool to cut channels in the XPS board to embed the T-shaped cables and connection cables. After embedding, secure them with tape.

- On-siteTesting (First Test)

After powering on, use an infrared thermometer to check the temperature of the heating film to determine if it is working correctly and heating evenly. If there is poor heating, check for loose connections.

With the power on, use a clamp meter to measure the leakage current of each thermostat circuit. The leakage current for each circuit should be less than 2mA. If it is greater than 2mA, check for any damage to the film caused during installation.

With the power off, use a multimeter to record the resistance of each heating film group to verify it is within the design range.

- Lay PET Film

Lay the PET protective film over the heating film to protect it. The seams between PET film sheets should be sealed with tape. The total thickness of the PET film must be greater than 300um. Before laying the PET film, clean the surface of the heating film to ensure it is free of any debris or particles.

- *Lay Heat Spreader Plates (Optional)

Laying heat spreader plates is an optional step. Using them can balance the temperature difference between film strips and also mitigate overheating issues caused by small-area coverings (large-area coverings are still prohibited).

The heat spreader plates (aluminum plates) should be thicker than 0.5mm, with dimensions of 50cm*100cm. They are placed between the

heating film strips, evenly distributed, with a gap of more than 5cm between plates. Secure the plates to the PET film with tape.

During installation, ensure the edges of the aluminum plates are smooth and free of burrs to prevent them from piercing the PET film.

- LayPE Waterproof Film

Lay the PE waterproof film to provide waterproof protection for the heating system. The PE film should cover the entire area, with overlapping sections secured with tape. The total thickness of the PE film must be greater than 80um. Before laying, clean the surface of the PET film to ensure it is free of any debris or particles.

- LayWooden Flooring

The wooden flooring should be installed immediately after the heating film installation is complete. Before laying the wooden floor, clean the surface of the PE film to ensure it is free of any debris or particles.

During the wooden floor installation, be careful to prevent wood chips, stones, or other particles from getting between the floor and the PE film. Be mindful not to damage the heating film with installation tools.

It is recommended to use reinforced laminate flooring specifically designed for underfloor heating, with a thickness not exceeding 12mm. (Solid wood flooring may develop gaps due to inconsistent moisture content and shrinkage. Excessively thick flooring will impede upward heat transfer, leading to slow heating and high temperatures in the heating film.)

- SecondaryTesting (Final Test

After the wooden floor installation is complete, conduct a second power-on test.

Use an infrared thermometer to check the temperature of the heating film to confirm it is working correctly and heating evenly. If there is poor heating, check for loose connections.

With the power on, use a clamp meter to measure the leakage current of each thermostat circuit. The leakage current for each circuit should be less than 2mA. If it is greater than 2mA, check for any damage to the film.

With the power off, use a megohmmeter to test the insulation resistance of the heating film. The reading should be greater than 2MΩ. If it is less than 2MΩ, it indicates that the heating film or wiring may be damaged.